вступ

CNC (Computer Numerical Control) machines have revolutionized the way manufacturing processes are carried out. From precise cuts to complex shapes, CNC machines are at the heart of modern manufacturing. In this article, we will explore the different types of CNC machines available, how they work, and their various applications. Whether you’re a factory owner or a distributor, understanding the types of CNC machines can help you make informed decisions about your equipment. Let’s dive into the world of CNC machining.

1. What Are CNC Machines?

CNC machines are automated tools that use a computer to control their movements and functions. Unlike manual machines, which require operators to control the cutting process directly, CNC machines use pre-programmed commands to produce parts with high precision. These machines can perform a wide range of operations such as drilling, milling, turning, and grinding.

But here’s the kicker—CNC machines offer unparalleled accuracy. They can produce parts with micron-level precision, which is crucial for industries like aerospace and medical manufacturing. This level of precision would be impossible with manual labor.

CNC machines have become a staple in industries that require high precision and repeatability. They are used for everything from small-scale prototypes to large-scale production runs. But what makes CNC machines so essential? The key lies in automation. Automation not only speeds up production but also reduces human error, making the process more cost-effective.

Table 1: Key Components of a CNC Machine

| Component | опис |

|---|---|

| Controller | The “brain” of the machine that processes the program instructions. |

| Motors | Drive the movement of the machine along its axes. |

| Spindle | Holds and rotates the tool that performs the cutting. |

| Toolholder | Secures the tool to the spindle. |

| Workpiece | The material being machined, such as metal, plastic, or wood. |

2. How Do CNC Machines Work?

Ready for the good part? Let’s break down how CNC machines actually work. It all begins with a design, typically created in CAD (Computer-Aided Design) software. This design is then converted into a set of instructions, known as G-code, which tells the machine exactly how to move, what tools to use, and how to interact with the material.

The CNC machine’s controller reads the G-code and directs the machine’s movements along multiple axes, allowing it to carve out intricate designs. Depending on the complexity of the design, a CNC machine can perform a variety of functions, including drilling holes, creating grooves, or even 3D printing parts.

What’s the real story behind the complexity? The machine itself is guided by a series of motors and sensors that monitor its movements. This ensures that the machine is following the instructions to a tee, which is what makes CNC machining so accurate.

Table 2: G-Code Functions in CNC Machines

| G-Code Function | опис |

|---|---|

| G0 | Rapid positioning (moves the tool quickly to a specified location) |

| G1 | Linear interpolation (moves the tool in a straight line) |

| G2 | Circular interpolation (moves the tool in a circular motion, clockwise) |

| G3 | Circular interpolation (moves the tool in a circular motion, counter-clockwise) |

3. What Are the Different Types of CNC Machines?

So, what types of CNC machines are out there? Well, it all depends on the job you need to complete. There are several types of CNC machines, each designed for specific tasks. These include CNC milling machines, CNC lathes, CNC routers, CNC plasma cutters, and CNC EDM (Electrical Discharge Machining) machines.

Each of these machines has its own set of capabilities and is suitable for different types of production runs. Whether you need precision machining or high-speed production, there’s a CNC machine that fits your needs.

This is where it gets interesting: CNC machines can be adapted for various industries, from automotive to medical to aerospace. Let’s look at a few of the most popular types of CNC machines.

Table 3: Types of CNC Machines and Their Uses

| CNC Machine Type | Common Uses |

|---|---|

| CNC Milling Machine | Used for cutting, drilling, and shaping materials such as metal, plastic, and wood. |

| Токарний верстат з ЧПУ | Used for turning operations, such as making cylindrical parts. |

| CNC Router | Primarily used for woodwork and softer materials, ideal for detailed cutting. |

| CNC Plasma Cutter | Used for cutting metal sheets and plates quickly and efficiently. |

| CNC EDM | Used for precise cutting of complex shapes, especially in hard materials. |

4. What Are CNC Milling Machines Used For?

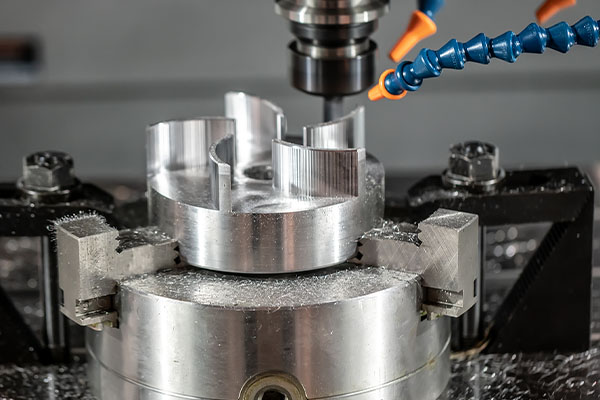

CNC milling machines are among the most commonly used machines in manufacturing. They are versatile and capable of performing a wide range of functions, including drilling, boring, and cutting. CNC milling machines are often used to create detailed parts that require precision and smooth finishes.

Here’s the kicker—CNC milling machines can work with a variety of materials, including metals, plastics, and composites. This makes them ideal for industries like automotive, aerospace, and defense. They can create intricate parts that would be difficult to produce with manual machines.

But what makes CNC milling so effective? The answer lies in its ability to perform multiple operations in one go. A CNC milling machine can not only drill holes but also cut complex shapes, all while maintaining high accuracy.

Table 4: Types of CNC Milling Machines

| Milling Machine Type | опис |

|---|---|

| Vertical Milling Machine | The spindle axis is vertical, ideal for tasks like drilling and contouring. |

| Horizontal Milling Machine | The spindle axis is horizontal, making it better for large-scale production. |

| Universal Milling Machine | Combines both vertical and horizontal movements for more flexibility. |

5. What Are CNC Lathes Used For?

CNC lathes are another essential type of machine used for precision manufacturing. Unlike milling machines, which move the material to the tool, CNC lathes rotate the material while the tool remains stationary. This is ideal for producing cylindrical or conical parts, such as shafts or rods.

What’s the real story? CNC lathes are perfect for high-volume production, thanks to their ability to create parts with tight tolerances. These machines can also perform a variety of functions, including drilling, threading, and boring.

Ready for the good part? CNC lathes are essential for industries that require large quantities of uniform parts, such as the automotive and electronics industries. Their ability to operate at high speeds and with great precision makes them a valuable tool in modern manufacturing.

Table 5: CNC Lathe Features

| Особливість | опис |

|---|---|

| Висока точність | Produces parts with tight tolerances, essential for critical applications. |

| Універсальність | Capable of performing a variety of operations such as drilling and threading. |

| Speed | Ideal for high-volume production runs. |

Висновок

In this article, we’ve explored the various types of CNC machines and their applications. Whether you need precision milling, turning, or cutting, there’s a CNC machine for every task. From CNC milling machines to CNC EDM, these machines are indispensable in modern manufacturing, helping industries achieve high levels of accuracy and efficiency.

So, what’s the takeaway? CNC machines have revolutionized the manufacturing industry by automating processes and reducing human error. They’ve become indispensable tools for producing high-quality parts, especially in industries like aerospace, automotive, and medical manufacturing. By understanding the different types of CNC machines and how they work, you can make better decisions when it comes to investing in equipment for your business.

6. What Are CNC Routers Used For?

CNC routers are versatile machines designed primarily for cutting, engraving, and carving a wide range of materials, including wood, plastic, composites, and sometimes metal. These machines are commonly used in woodworking, cabinetry, and the production of detailed signs. Ready for the good part? The key advantage of a CNC router is its ability to perform both complex and high-speed cutting, which is ideal for industries that require detailed craftsmanship.

CNC routers excel at creating intricate patterns and shapes, thanks to their ability to work with large, flat materials. They are often used to create signs, furniture, and other detailed products that require precise measurements and high-quality finishes. Another notable advantage is their relatively low cost when compared to other CNC machines, making them an attractive option for small businesses or hobbyists.

What’s the real story behind CNC routers? Their flexibility allows them to be customized for various production needs, making them ideal for both large-scale commercial operations and small-scale workshops. For example, in woodworking, a CNC router can be used to carve out intricate designs or to cut out simple shapes for furniture assembly.

Table 6: Applications of CNC Routers

| матеріал | застосування |

|---|---|

| Wood | Furniture production, signage, cabinetry |

| Plastic | Prototyping, display models, cutouts |

| Composite Materials | Automotive parts, aerospace components |

| Алюміній | Lightweight structures, custom parts |

7. What Is CNC Plasma Cutting?

CNC plasma cutting is a process used to cut through electrically conductive materials, such as steel, aluminum, brass, and copper. Plasma cutters use high-powered plasma arcs to melt the material, which is then blown away by a high-pressure stream of air. So, what makes CNC plasma cutting stand out? The answer lies in its ability to cut through thicker materials at much higher speeds than traditional methods, making it a great option for high-volume production.

The precision and speed of CNC plasma cutting make it a top choice for industries like automotive, metal fabrication, and construction. What’s the kicker? Plasma cutting is especially useful for large sheets of material, where intricate cuts are needed with minimal distortion. The automated nature of CNC plasma cutting ensures consistent cuts across large production runs, making it efficient and cost-effective.

But here’s the interesting part: CNC plasma cutting has become a popular option in industries requiring both high precision and efficiency. Whether you’re cutting metal for industrial machinery or automotive parts, CNC plasma cutting is an invaluable tool in modern manufacturing.

Table 7: Benefits of CNC Plasma Cutting

| Вигода | опис |

|---|---|

| Speed | Cuts through thick materials quickly, ideal for high-volume production. |

| Точність | Provides accurate cuts with minimal distortion. |

| Cost-effective | Ideal for large-scale production and heavy-duty cutting. |

8. What Is CNC EDM?

CNC EDM (Electrical Discharge Machining) is a highly precise method used to machine hard metals that are difficult to process with traditional methods. EDM uses electrical discharges to shape the material by eroding it away with a series of rapid electric sparks. Ready for the good part? CNC EDM allows for extremely intricate and complex shapes to be produced, which is why it’s particularly useful in industries that demand high precision.

CNC EDM is commonly used for creating molds, dies, and parts with extremely tight tolerances. What’s the kicker? Its ability to work with hard materials, such as tool steel, carbide, and titanium, makes it indispensable in industries like aerospace and defense, where complex shapes and materials are the norm.

What’s the real story here? CNC EDM machines can produce parts with incredibly fine detail and finish, making them a top choice for manufacturers requiring high-quality results. This process has become a game-changer for industries dealing with tough materials that other machining methods can’t handle effectively.

Table 8: Key Features of CNC EDM

| Особливість | опис |

|---|---|

| Висока точність | Produces parts with micron-level accuracy. |

| Material Versatility | Can machine hard metals like titanium and carbide. |

| Intricate Shapes | Ideal for making complex parts like molds and dies. |

9. How Are CNC Machines Programmed?

CNC machines are powered by precise instructions encoded in a program, typically written in G-code. So, what’s the real story behind programming these machines? It begins with a CAD design that is converted into G-code through CAM (Computer-Aided Manufacturing) software. The G-code then controls the CNC machine’s movements, tool changes, and other parameters.

The process of programming CNC machines is essential to ensuring that the machine produces parts to exact specifications. Ready for the good part? The software used for CNC programming allows manufacturers to visualize the entire process before a part is even produced, reducing the likelihood of errors and improving efficiency. This is a major advantage, as it allows for quick corrections before the machine starts running, saving both time and resources.

Programming a CNC machine requires a certain level of expertise, but modern software has made it easier for operators to quickly learn the basics. Many machines now come equipped with simulation features that help guide the programmer and prevent mistakes.

Table 9: Common G-Codes in CNC Programming

| G-Code | опис |

|---|---|

| G0 | Rapid movement to a specified position. |

| G1 | Linear cutting movement. |

| G2 | Circular cutting, clockwise. |

| G3 | Circular cutting, counterclockwise. |

10. What Are the Benefits of Using CNC Machines?

Ready for the good part? Let’s talk about the main reasons why manufacturers swear by CNC machines. The key benefits of using CNC machines include their precision, speed, and ability to handle complex tasks with ease. Whether you’re in automotive manufacturing or producing medical devices, CNC machines help ensure that parts are made with accuracy and consistency.

CNC machines are also highly efficient. Once the machine is programmed, it can run continuously, producing parts with minimal supervision. What’s the kicker? The ability to run automated production cycles not only saves time but also reduces human error. This makes CNC machining an invaluable tool in industries where precision and reliability are critical.

But here’s where it gets interesting: the versatility of CNC machines also plays a huge role in their success. With a wide range of available machine types, manufacturers can tackle nearly any project, no matter how complex or detailed.

Table 10: Advantages of CNC Machines

| Advantage | опис |

|---|---|

| Точність | CNC machines can produce parts with high accuracy and tight tolerances. |

| Ефективність | Automated processes lead to faster production with less downtime. |

| Універсальність | Capable of working with a wide range of materials and performing diverse tasks. |

11. What Are the Limitations of CNC Machines?

CNC machines are powerful tools, but they do come with limitations. One of the biggest challenges is the high upfront cost. Ready for the good part? While the initial investment in CNC machinery can be significant, the long-term benefits often outweigh the costs, especially when it comes to large-scale production.

Another limitation is the need for skilled operators. CNC machines may be automated, but they still require trained personnel to program and maintain them. What’s the kicker? For smaller businesses or startups, the training required to operate CNC machines can be a barrier to entry. However, with the right training and resources, the benefits of CNC machining can quickly become apparent.

CNC machines also require regular maintenance. Over time, parts may wear down and need to be replaced. But here’s the interesting part—proper maintenance ensures that the machines continue to run efficiently, which minimizes downtime and repair costs in the long run.

Table 11: Challenges of Using CNC Machines

| Виклик | Рішення |

|---|---|

| High initial cost | Long-term savings through increased productivity and precision. |

| Skilled labor shortage | Provide training and hire experienced operators. |

| Maintenance costs | Regular maintenance and timely part replacements to avoid downtime. |

12. What Industries Use CNC Machines?

What’s the real story? CNC machines are essential in a wide variety of industries. Aerospace, automotive, medical devices, and electronics are just a few sectors that benefit from the precision and speed CNC machines offer. The versatility of CNC machines makes them ideal for producing everything from intricate components to large structural parts.

In the aerospace industry, for example, CNC machines are used to create components that require extreme precision, such as turbine blades or fuselage sections. What’s the kicker? Even a tiny error in these parts could lead to catastrophic failures, which is why CNC machines are the go-to choice for manufacturers in the industry.

Ready for the good part? The automotive sector also relies heavily on CNC machines for the production of components like engine blocks, chassis parts, and even interior elements. This level of automation and precision ensures that the vehicles we drive are safe and reliable.

Table 12: Industries That Benefit from CNC Machines

| Промисловість | застосування |

|---|---|

| Аерокосмічна | Aircraft components, turbine blades, fuselage sections |

| Автомобільний | Engine blocks, chassis parts, interior components |

| Medical Devices | Surgical instruments, implants, diagnostic tools |

| Electronics | Circuit boards, connectors, sensors |

13. How to Choose the Right CNC Machine for Your Needs?

Choosing the right CNC machine can be a daunting task, especially with so many options available. Ready for the good part? The first step is to assess your needs. What type of materials will you be working with? What level of precision do you require? These factors will help guide your decision.

CNC machines vary in size, complexity, and capabilities, so it’s important to find one that matches your production goals. What’s the kicker? A CNC machine that’s too complex for your needs can be a waste of money, while one that’s too simple might not provide the precision you require. Finding the right balance is key.

Another consideration is the machine’s automation level. Ready for the good part? Some machines require more manual intervention, while others are fully automated. If you’re looking to maximize efficiency, choosing a more automated machine can help you achieve your goals faster and more accurately.

Table 13: Factors to Consider When Choosing a CNC Machine

| Фактор | Розгляд |

|---|---|

| матеріал | Different machines are suited for different materials (metal, wood, plastic). |

| Точність | Consider how tight the tolerances need to be for your parts. |

| автоматизація | Fully automated machines are ideal for high-volume production. |

14. What Are the Safety Considerations with CNC Machines?

Safety is paramount when working with CNC machines. These machines are powerful, and improper use can lead to serious accidents. So, what makes CNC machines dangerous? The main risk comes from the rotating parts and high-speed movements, which can cause injury if proper safety protocols are not followed.

Ready for the good part? Modern CNC machines come with built-in safety features, including automatic shut-offs, emergency stops, and protective barriers. But here’s the kicker—training is key. Operators must be properly trained to use the machines safely and efficiently.

CNC operators must also wear personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. What’s the real story here? By following safety protocols and investing in training, the risk of accidents can be significantly minimized.

Table 14: Safety Features of CNC Machines

| Safety Feature | опис |

|---|---|

| Emergency Stop | Allows operators to quickly stop the machine in case of an emergency. |

| Protective Barriers | Shields operators from moving parts and debris. |

| Automatic Shutoff | Stops the machine if it detects a malfunction or issue. |

15. How Has CNC Technology Evolved Over Time?

CNC technology has come a long way since its inception in the 1950s. Ready for the good part? Early CNC machines were manually programmed using punch cards, and today, CNC machines are operated through sophisticated computer software that can handle complex tasks with ease.

What’s the kicker? CNC machines have become faster, more accurate, and more versatile over the years. With the introduction of multi-axis machines, manufacturers can now create parts with much more complex geometries than ever before. What’s the real story behind this evolution? The continuous advancements in automation and robotics are shaping the future of CNC machining, making it more efficient and cost-effective.

Ready for the good part? The future of CNC technology looks bright, with the integration of AI, machine learning, and 3D printing capabilities. These innovations will continue to push the boundaries of what CNC machines can do, leading to even more accurate and efficient manufacturing processes.

Table 15: Evolution of CNC Technology

| Year | Milestone |

|---|---|

| 1950s | Introduction of the first CNC machines, operated with punch cards. |

| 1980s | Emergence of computer-aided design (CAD) and computer-aided manufacturing (CAM). |

| 2000s | Introduction of multi-axis CNC machines, enabling complex geometries. |

FAQ

Q1: Що таке верстат з ЧПК?

A CNC (Computer Numerical Control) machine is an automated tool that uses computer programming to control its movements and perform tasks such as cutting, drilling, and milling.

Q2: How do CNC machines work?

CNC machines are controlled by a computer program that instructs them on how to move, cut, and shape the material. The program, typically written in G-code, guides the machine to perform the desired operation.

Q3: What are the different types of CNC machines?

Common types of CNC machines include CNC milling machines, CNC lathes, CNC routers, CNC plasma cutters, and CNC EDM machines. Each type is used for specific tasks such as cutting, drilling, or turning.

Q4: What industries use CNC machines?

CNC machines are used in various industries including automotive, aerospace, medical, and electronics for precise manufacturing and high-volume production.

Q5: How do I choose the right CNC machine for my business?

Choosing the right CNC machine depends on the materials you work with, the complexity of the parts you need to produce, and the scale of your production. Consider factors like precision, speed, and cost.