вступ

Finding the right CNC precision machining provider can feel overwhelming, especially with so many options available. Whether you’re looking to produce custom parts for your business or simply need a reliable partner for ongoing production, it’s crucial to ensure you’re working with a trusted company. Here’s the deal: choosing the best provider doesn’t have to be difficult if you know what to look for. This guide breaks down everything you need to know, from understanding the machining process to evaluating potential providers. By the end, you’ll be equipped to make an informed decision and select the right provider for your needs.

What Is CNC Precision Machining?

The Basics of CNC Machining

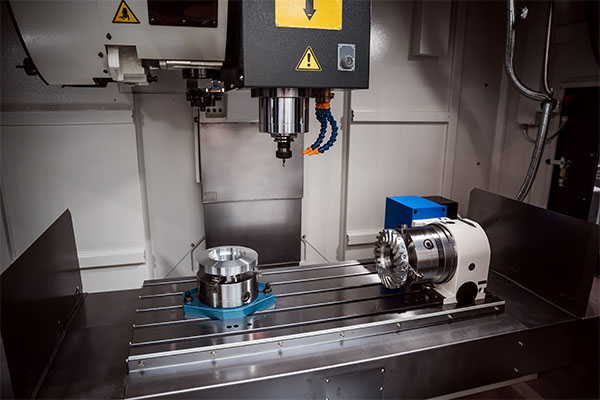

CNC precision machining is a process that uses computer-controlled machines to manufacture parts with high accuracy and precision. The term “CNC” stands for Computer Numerical Control, which refers to the system used to automate the operation of machines such as lathes, mills, and grinders. CNC machining has revolutionized industries by making it easier to produce parts with tight tolerances and complex geometries.

How CNC Machining Works

At its core, CNC machining involves converting a digital design into a physical part. A CAD (Computer-Aided Design) file is created, which is then translated into instructions for the CNC machine. These instructions tell the machine exactly how to cut, drill, or shape the material to match the specifications in the design. Іншими словами, CNC machining is all about precision, accuracy, and repeatability.

Types of CNC Machining

There are several types of CNC machining processes, each with its own strengths and applications. Some of the most common include:

- Фрезерування з ЧПУ: Uses rotary cutters to remove material from a workpiece. Ideal for creating parts with complex shapes and features.

- Токарна обробка з ЧПУ: Involves rotating the workpiece while a cutting tool removes material. Perfect for cylindrical parts like shafts and pins.

- CNC Drilling: A machining process used to create holes in a workpiece. It’s often used in conjunction with milling or turning processes.

- CNC Grinding: Uses an abrasive wheel to remove material and is primarily used for finishing operations.

Why Precision Matters in CNC Machining

The Importance of Precision

In CNC machining, precision refers to how accurately the machine can replicate the dimensions of a part based on the design. When you need parts that fit perfectly or function flawlessly, precision is key. Precision ensures that each part fits seamlessly into an assembly and performs as expected, which is especially important in industries like aerospace, automotive, and medical device manufacturing.

Applications Requiring High Precision

Certain industries rely heavily on CNC machining’s ability to produce precise parts. Aerospace, for instance, requires extremely tight tolerances because any deviation could compromise safety. The automotive industry also requires high precision to ensure parts work together perfectly. In medical device manufacturing, CNC machining ensures parts like implants or surgical tools meet exact standards for functionality and safety.

How Precision Impacts Product Quality

The link between precision machining and product quality cannot be overstated. When a part is machined with precision, it performs better, lasts longer, and functions exactly as intended. This is particularly critical when parts are part of larger, more complex systems, such as engines or medical equipment. For example, a slight inaccuracy in a part used in a car engine could lead to mechanical failure, resulting in costly repairs or even safety hazards.

Key Factors to Consider When Choosing a CNC Machining Provider

Quality of Service

One of the most critical factors in selecting a CNC machining provider is the quality of service. Вам може бути цікаво how you can ensure that the provider delivers quality results. A provider with a strong reputation for delivering high-quality parts on time is often a good indicator of their overall service quality. Quality assurance processes, like ISO 9001 certification, show that the provider has standardized practices in place to ensure consistent results.

Experience in Your Specific Industry

Not all CNC machining providers are equipped to handle the needs of every industry. It’s important to choose a provider with experience in the specific requirements of your industry. For example, a provider with experience in medical device manufacturing may be familiar with the high precision and specific regulatory standards required in that field, making them a better choice than a provider who specializes in automotive parts.

Capacity and Capabilities

Can the provider handle your order volume and complexity? Ось угода: different CNC machining providers have varying capacities. Some specialize in small batch runs, while others handle large-scale production. If you’re planning for large orders or high-mix, low-volume production, you’ll need a provider that can scale accordingly. It’s also important to evaluate the capabilities of their machines—can they work with the materials and part designs you need?

Certifications and Standards

When evaluating potential CNC providers, look for certifications such as ISO 9001 or AS9100, which demonstrate a commitment to quality. These certifications indicate that the provider follows strict quality management processes and is capable of meeting industry-specific standards. If your parts need to comply with regulatory standards, such as those in aerospace or medical device manufacturing, ensure the provider is experienced in meeting those standards.

Understanding CNC Machining Costs and How They Are Determined

Factors Influencing Pricing

The cost of CNC machining can vary widely depending on several factors. These include the type of material used, the complexity of the part, and the time it takes to machine the part. The more intricate the design, the higher the machining cost. For example, creating a part with complex geometries or multiple features will generally be more expensive than machining a simple, straightforward part.

Cost Estimation Process

Reliable CNC machining providers have a process for estimating costs based on the specifications of the project. They consider the cost of materials, labor, machine time, and tooling. Вам може бути цікаво how these factors come together to form the total price. Some providers may charge by the hour for machine time, while others may offer fixed pricing for specific jobs. Regardless, it’s important to get a detailed breakdown of the costs so you can make an informed decision.

Hidden Costs to Watch Out For

In some cases, hidden costs can arise during the machining process. Watch out for additional charges such as setup fees, tooling costs, or rush fees for expedited orders. These costs can add up quickly, so it’s important to clarify all potential charges upfront before committing to a provider.

Assessing the Experience and Reputation of a CNC Machining Service

Years in Business and Expertise

Experience matters when it comes to CNC machining. Ось угода: a company with years of experience is more likely to have the knowledge and expertise necessary to deliver high-quality results. Look for providers that have been in business for several years and have a proven track record of success in your industry. The more experienced they are, the more likely they’ll be able to handle any challenges that arise during the machining process.

Client Reviews and Testimonials

One of the best ways to assess a provider’s reputation is by reading client reviews and testimonials. Вам може бути цікаво where to find reliable reviews. Check the provider’s website, industry forums, and social media for feedback from past clients. Positive reviews are a good indicator that the provider consistently delivers high-quality products and excellent customer service.

Industry Recognition and Awards

In addition to client reviews, look for industry recognition and awards. These honors indicate that the provider is highly regarded within the industry and adheres to the highest standards. Awards and certifications from reputable organizations serve as a mark of credibility and reliability.

How to Evaluate CNC Machining Equipment and Technology

Types of CNC Machines and Their Capabilities

Different types of CNC machines are designed for different tasks. What do you need to know about the equipment used by a provider? If you need high-precision parts, look for a provider that uses high-quality CNC machines capable of meeting your specifications. CNC milling machines, CNC lathes, and multi-axis machines each offer different capabilities that may be more suitable depending on your part design and material requirements.

Automation and Software

The software and automation systems used by a CNC machining provider can significantly impact the efficiency and quality of the machining process. Ось угода: the latest CAD/CAM software ensures that designs are accurately translated into machine instructions, reducing the risk of errors. Automation in the form of robotic arms or conveyor systems can also speed up production times and improve consistency.

Tooling and Maintenance Practices

Tooling refers to the specific tools and dies used to shape the material. Високоякісний інструмент is essential for achieving precise cuts and finishes. It’s important to inquire about the maintenance practices of the provider—machines that are regularly serviced and maintained perform better and are less likely to experience downtime.

Evaluating Lead Times and Turnaround Times

What is the Expected Lead Time for a Project?

Lead time refers to the amount of time it takes for a provider to complete a machining project from start to finish. Вам може бути цікаво how long it will take to receive your parts. Lead times can vary depending on the complexity of the part, the provider’s workload, and the materials used. Make sure to clarify the expected lead time before placing an order.

Impact of Complexity on Turnaround Time

More complex parts take longer to machine. If your part requires intricate features, expect the lead time to be longer. On the other hand, simpler parts with straightforward designs will generally have a shorter turnaround time. Keep in mind that expedited services may be available for urgent orders, but these often come with additional costs.

Fast-Turnaround Services

Some CNC machining providers specialize in fast-turnaround services, which can be a lifesaver when you’re on a tight deadline. Ось угода: if you need parts quickly, look for providers who offer rapid prototyping or quick-turn services. Just be aware that these services may come at a premium, so make sure to factor that into your budget.

Assessing Communication and Customer Support

Clear Communication

Effective communication is essential for a successful project. Вам може бути цікаво what good communication looks like. A provider should be responsive to your inquiries, proactive in addressing potential issues, and clear in explaining the project timeline and costs. Transparent communication reduces the chances of misunderstandings and ensures that you’re both on the same page.

Responsiveness and Availability

When you have a question or concern, you need a provider that responds promptly. You need a provider that is readily available to answer your questions and provide updates. Look for providers that offer dedicated account managers or customer support teams to assist throughout the project.

Support Throughout the Project

Customer support doesn’t end once the contract is signed. Support throughout the project ensures that any issues or changes are addressed quickly. Whether it’s technical support, design revisions, or delivery issues, a good provider will be there every step of the way to ensure the project goes smoothly.

Quality Control and Inspection Processes

Standard Quality Control Measures

Quality control is a critical part of CNC machining, as it ensures that the final product meets the required specifications. When you need precision, look for providers that implement rigorous quality control processes. This may include visual inspections, dimension checks, and functional testing to verify the part’s performance.

Types of Inspection Tools and Technologies Used

CNC machining providers use a variety of inspection tools to verify part quality. Coordinate measuring machines (CMMs), optical comparators, and laser scanning systems are just a few of the tools that may be used to measure critical dimensions. The right tools ensure that every part is produced with the utmost accuracy.

Consistency in Quality

Quality control isn’t just about individual parts—it’s about maintaining consistency throughout the production process. Ось угода: make sure that the provider has systems in place to monitor quality over time. Consistent quality is key when placing repeat orders or producing parts in large quantities.

Customization and Design Flexibility in CNC Machining

Working with Custom Designs

If your project requires custom parts or designs, it’s essential to work with a CNC machining provider who has experience handling custom work. Вам може бути цікаво how to find a provider that can handle your specific design requirements. Look for a provider that offers flexibility and can accommodate changes to the design as needed.

Material Options

CNC machining is compatible with a wide range of materials, from metals to plastics to composites. Ось угода: choose a provider who offers the materials you need and has the expertise to work with them. Some providers specialize in specific materials, while others can handle a broad range of options.

Post-Machining Services

Post-machining services can add significant value to your order. Вам може бути цікаво if the provider offers additional services such as assembly, finishing, or coating. Providers who offer these services can save you time and effort, allowing you to receive your parts ready for use.

Understanding the Impact of Volume on CNC Machining Services

Small-Batch vs Large-Batch Production

Whether you need a few prototypes or a large production run, CNC machining can accommodate both small and large orders. The deal here is that small-batch runs often require higher per-unit costs due to setup and tooling expenses. However, large-batch runs benefit from economies of scale, making them more cost-effective.

When to Consider Mass Production

If you’re considering mass production, it’s essential to evaluate the capacity of the CNC provider. Mass production requires efficient workflows, quick turnaround times, and consistent quality. Look for a provider who specializes in large-scale manufacturing if you anticipate high volume orders.

Scalability

Scalability is crucial for businesses that may need to increase their order quantities over time. Ось угода: look for a CNC provider who can scale with your business. Whether you’re starting small or planning to increase production, the provider should be able to adjust to your changing needs.

Delivery and Shipping Options

Shipping Methods and Lead Time

Shipping is a crucial consideration when choosing a CNC machining provider. Вам може бути цікаво how your parts will be shipped once they are complete. Providers typically offer different shipping methods based on urgency and cost. Make sure to clarify shipping options upfront to avoid delays.

International Shipping

For businesses that operate internationally, it’s essential to find a provider who can handle international shipping. Ось угода: some CNC machining providers specialize in international logistics, making it easier to get your parts delivered worldwide without hassle.

Tracking and Packaging

Good packaging is essential to ensure your parts arrive in perfect condition. Look for a provider that offers secure packaging and tracking services so you can monitor the progress of your shipment.

Sustainability and Environmental Practices in CNC Machining

Eco-Friendly Machining Processes

Sustainability is becoming increasingly important in manufacturing, and CNC machining is no exception. Вам може бути цікаво how CNC machining can be sustainable. Some providers use eco-friendly practices such as reducing energy consumption and minimizing waste during production.

Recycling and Waste Management

CNC machining can generate waste material, such as metal shavings or plastic scraps. You need to know if your provider has waste management systems in place to recycle materials and reduce the environmental impact.

Energy-Efficient Practices

Ось угода: energy-efficient CNC machines can reduce the overall environmental footprint of the machining process. Look for providers who invest in energy-efficient equipment and practices to minimize energy consumption.

The Benefits of Local vs. Overseas CNC Machining Providers

Local vs Overseas Manufacturing

When choosing a CNC machining provider, one important consideration is whether to choose a local or overseas supplier. Here’s the deal: working with a local provider offers the benefit of faster shipping times and easier communication, while overseas providers may offer lower costs.

Cost vs Convenience

Choosing between local and overseas providers often comes down to a trade-off between cost and convenience. Вам може бути цікаво if the savings from overseas machining are worth the potential delays and communication challenges. It depends on your project’s needs, but you should weigh the pros and cons carefully.

Language Barriers and Cultural Differences

When working with overseas providers, watch out for potential language barriers and cultural differences that might impact communication. If smooth, clear communication is critical, you might prefer a local supplier.

Final Checklist: How to Choose the Right CNC Machining Provider for Your Business

Summarize Key Factors to Consider

Choosing the right CNC machining provider requires considering several key factors, including quality, experience, and pricing. Ось угода: make sure the provider you choose meets your specific needs and can deliver the results you require.

Red Flags to Watch Out For

Look out for red flags such as a lack of transparency in pricing or poor customer reviews. If something feels off, it might be a sign that the provider isn’t right for your project.

Making the Final Decision

Once you’ve narrowed down your options, make sure to compare the providers based on all the factors discussed. Choose the provider that offers the best balance of price, quality, and service for your specific needs.

Next Steps

Once you’ve selected a provider, reach out and start the conversation. Clarify all details upfront to avoid any surprises along the way.

Висновок

Choosing the right CNC machining provider doesn’t have to be complicated. By considering factors like experience, quality, and pricing, you can make an informed decision that meets your needs. Don’t rush—take the time to evaluate each provider carefully. In the end, the right choice will save you time, money, and ensure your parts are made to the highest standards.

Розділ FAQ

- What industries benefit from CNC precision machining?

CNC precision machining is used across various industries that require high accuracy and complex designs. These include aerospace, automotive, medical device manufacturing, electronics, defense, and energy. Each of these industries relies on CNC machining to produce critical parts with tight tolerances and excellent quality. - How do I know if a CNC machining provider is reliable?

To determine if a CNC machining provider is reliable, check for client reviews and testimonials. It’s also beneficial to look at their certifications, such as ISO 9001, which indicate their commitment to quality. Ask for references and evaluate the consistency of their past work, paying attention to their delivery timelines and communication throughout the process. - What materials are typically used in CNC machining?

CNC machining can work with a wide range of materials including metals like aluminum, steel, titanium, and brass. It also works with plastics such as acrylic, polycarbonate, and ABS, as well as composite materials like carbon fiber. The choice of material depends on the specific requirements of your project. - What is the difference between CNC machining and manual machining?

The key difference between CNC machining and manual machining is automation. CNC machining is computer-controlled, offering more precise, repeatable results with minimal human intervention. Manual machining, on the other hand, requires a skilled machinist to operate the machine, which can be more time-consuming and prone to human error. CNC machining is ideal for high-precision and complex parts. - How can I ensure that the final product meets my specifications?

To ensure the final product meets your specifications, work with a CNC provider that has strong quality control processes in place. They should perform detailed inspections at various stages of the machining process. Request a prototype or sample before full production to verify the dimensions and functionality of the part. - What should I do if my project requires custom designs?

If your project requires custom designs, communicate your needs clearly with the CNC provider. Provide detailed CAD files and be prepared for design revisions. The provider should be able to assist with the design process, ensuring that the final product can be manufactured accurately. It’s also essential that they have the capability to work with the materials and processes needed for custom parts. - How long does it take for CNC machining to complete a project?

The time it takes to complete a CNC machining project depends on several factors, including the complexity of the part, the materials used, and the production volume. For simple parts, it could take only a few days, but more intricate designs or larger production runs could take several weeks. Always ask for an estimated lead time before starting the project. - Can CNC machining providers handle international shipping?

Yes, many CNC machining providers are equipped to handle international shipping. It’s important to clarify shipping arrangements upfront, including potential shipping costs, customs duties, and expected delivery times. Some providers may even offer support with logistics to ensure your parts arrive safely and on time. - What are the environmental impacts of CNC machining?

CNC machining, like any manufacturing process, has an environmental impact, particularly in terms of energy consumption and waste generation. However, many providers are implementing eco-friendly practices, such as using energy-efficient machinery, recycling metal shavings, and reducing material waste. Look for a provider who emphasizes sustainability and environmental responsibility in their operations. - Are there any risks to choosing a cheaper CNC machining provider?

Choosing a cheaper CNC machining provider may save money upfront, but there are potential risks, including lower-quality parts, longer lead times, and poor customer service. Ось угода: the cheapest option might cut corners on quality control, which can lead to defects and additional costs down the line. Always balance cost with quality and reliability to ensure your project meets your expectations.