Токарна обробка з ЧПУ

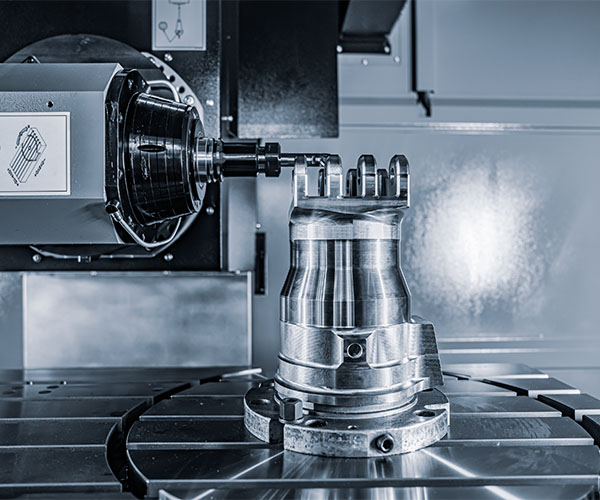

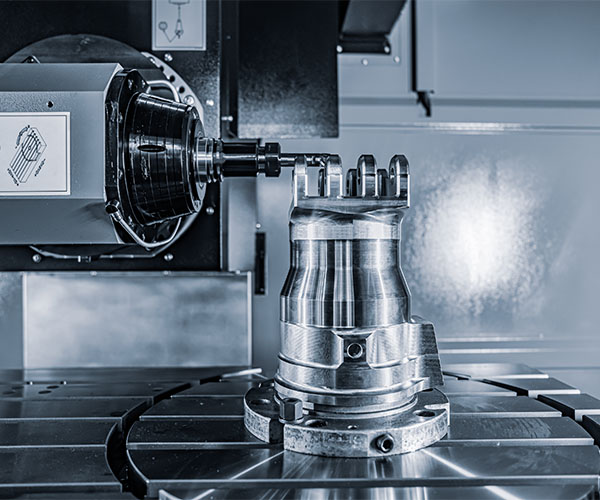

Precision CNC Lathe Machining Solutions

Experience high-accuracy CNC lathe machining designed for complex shapes and tight tolerances. Our advanced equipment ensures efficient production, consistent quality, and exceptional precision for every component. Trust us for reliable solutions tailored to your manufacturing needs.

What is CNC Lathe Turning?

10+ Years of Experience

Токарний верстат з ЧПУ is a precision manufacturing process where a cutting tool removes material from a rotating workpiece to create cylindrical parts. Controlled by Computer Numerical Control (CNC) technology, the process ensures accuracy, repeatability, and efficiency. CNC turning machines, or lathes, can produce intricate designs, including threads, grooves, and tapers, with tight tolerances. This method is widely used in industries like automotive, aerospace, and electronics to create components such as shafts, bushings, and fasteners. CNC turning offers high productivity, reduced material waste, and consistent quality, making it ideal for both prototyping and mass production.

Lathe Turning Machining Advantage

Lathe machining offers high точність, excellent ефективність, and the ability to produce complex components with tight tolerances. It handles various materials, supports both prototyping і mass production, and ensures consistent quality. Advanced CNC lathe machining reduces errors, speeds up production, and delivers cost-effective solutions across industries.

- 10+ Years of Experience

- Fast, Efficient, and Reliable Production

- Master Complex Shapes with Ease

- Guaranteed Consistency in Every Batch

- Adaptable to Multiple Materials

- Cost-Effective Solutions for Maximum Value

Specifications

Precision CNC Lathe Machining Manufacturing for Custom Specifications

Our precision CNC lathe machining shop specializes in delivering accurate and reliable machining solutions, meeting diverse size and design requirements with exceptional quality control.

Maximum part size for CNC turning

CNC turning design guidelines

Part size limitations

Metric units

Imperial units

Особливість

Recommended size

Feasible size

Maximum part diameter

431 mm

17 in

Min. feature size

Ø 2.5 mm

Ø 0.50 mm

Maximum part length

990 mm

39 in

Internal edges

R 8 mm

R 0.25 mm

Maximum spindle through-hole

40 mm

1.5 in

Holes

Diameter: standard drill bit sizes

Depth: 4 x diameter

Diameter: Ø 0.5 Depth: 10 x diameter

Maximum swing over the carriage

350 mm

13.7 in

Minimum wall thickness

0.8 mm (for metals) 1.5 mm (for plastics)

0.5 mm (for metals) 1.0 mm (for plastics)

Maximum speed: 1700RPM, Motor power: 640W

Threads

Size: M6 or larger Length: 3 x diameter

Size: M2

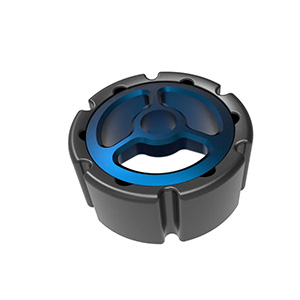

Reliable Precision CNC Lathe Machining Manufacturing

We specialize in producing high-quality CNC lathe machining parts with exceptional accuracy and efficiency. Our precision CNC lathe machining manufacturing process ensures consistent results, meeting tight tolerances and diverse industry requirements. Trust us for reliable performance and superior craftsmanship in every component.

Aluminum Lathe Machining

Brass Lathe Machining

Bronze Lathe Machining

Copper Lathe Machining

POM Lathe Machining

PVC Lathe Machining

Versatile Materials for CNC Lathe Machining

We offer a wide range of high-quality materials for CNC lathe machining, including metals, plastics, and alloys. Each material is carefully selected to ensure durability, precision, and optimal performance, meeting the unique requirements of your project. Trust us to deliver reliable results with the right material for every application.

Metals

Common Types:

- Алюміній

- Stainless Steel

- Латунь

- Copper

- Титан

Advantages:

- Excellent strength and durability

- High precision and dimensional stability

- Good resistance to wear and corrosion

- Suitable for complex and intricate designs

Applications:

- Automotive: Engine components, shafts, and fittings

- Aerospace: Aircraft parts and precision fittings

- Medical: Surgical tools and implants

- Electronics: Connectors and heat sinks

Plastics

Common Types:

- ABS

- POM (Delrin)

- Nylon

- PTFE (Teflon)

- Polycarbonate (PC)

Advantages:

- Lightweight and easy to machine

- Excellent chemical resistance

- Low friction and self-lubricating properties

- Cost-effective for prototyping and mass production

Applications:

- Medical: Insulation components and device housings

- Automotive: Lightweight structural parts

- Electronics: Insulating parts and connectors

- Consumer Goods: Durable and precision plastic parts

Tolerances

Precision CNC Machining Solutions with ISO 2768 Standards

We specialize in metal and plastic lathe machining, strictly adhering to ISO 2768 standards for precision and consistency. Our advanced CNC machining capabilities ensure reliable performance, tight tolerances, and superior quality, meeting the demands of industrial applications with efficiency and accuracy.

Limits for nominal size

Plastics (ISO 2768- m)

Metals (ISO 2768- f)

0.5mm to 3mm

±0.1mm

±0.05mm

Over 3mm to 6mm

±0.1mm

±0.05mm

Over 6mm to 30mm

±0.2mm

±0.1mm

Over 30mm to 120mm

±0.3mm

±0.15mm

Over 120mm to 400mm

±0.5mm

±0.2mm

Over 400mm to 1000mm

±0.8mm

±0.3mm

Over 1000mm to 2000mm

±1.2mm

±0.5mm

Over 2000mm to 4000mm

±1.2mm

/

*Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing.

Challenges & Solutions

Solving Key Challenges in Lathe Machining Operations

Our lathe machining services address common industry pain points, such as inconsistent precision, slow turnaround times, and material inefficiencies. With advanced lathe machining processes and skilled expertise, we ensure accurate results, streamlined operations, and dependable performance for every project.

Precision Control

Advanced technology ensures tight tolerances in every lathe machining process.

Fast Turnaround

Streamlined operations guarantee quick and efficient project delivery.

Material Versatility

Expertise in both metal and plastic lathe machining services.

Consistent Quality

Strict quality control ensures reliable and repeatable results.

Lathe Machining Service

Explore our professional lathe machining service through an engaging video. See how our precision, efficiency, and expertise deliver reliable results for every project.

Standards

Excellence in Precision CNC Lathe Machining Manufacturing

We specialize in precision CNC lathe machining manufacturing, maintaining strict quality standards throughout every stage of production. Each custom part undergoes rigorous inspections to ensure exceptional accuracy and consistency.

*** Multiple surface finishes are available to enhance both functionality and appearance.

*** Every part is meticulously checked on-site following our strict guidelines.

*** Inspection reports and quality documentation are available upon request, ensuring full compliance and transparency.

We are committed to delivering reliable and high-quality machining solutions for every project.

Common Questions

Frequently Asked Questions About Lathe Machining

Our CNC lathe machining services deliver precision, efficiency, and reliability for a wide range of industries. Utilizing advanced lathe machining tools and optimized lathe machining processes, we ensure each component meets strict quality standards. Whether working with metals or plastics, our team guarantees consistent results, fast turnaround times, and exceptional performance for every project.

Lathe machining tools are essential for shaping, cutting, and finishing materials, ensuring precision and consistency in the machining process.

The lathe machining process involves rotating a workpiece while a cutting tool removes material to achieve the desired shape and dimensions.

CNC lathe machining offers high precision, repeatability, and efficiency, making it ideal for complex and large-scale production tasks.

CNC lathe machining supports a wide range of materials, including metals, plastics, and composites, for versatile manufacturing applications.

We follow strict quality control measures, including inspections and adherence to international standards, to guarantee accuracy and reliability.

Industries such as automotive, aerospace, electronics, and medical manufacturing rely on CNC lathe machining for precise and durable components.