Introduction: The Need for Precision in Automotive Parts Manufacturing

When it comes to the automotive industry, precision in every component is crucial. Whether it’s for performance, safety, or reliability, the smallest deviation in a part’s specifications can result in failures or costly repairs. This is where custom CNC machining comes into play, offering solutions that meet the exacting standards of modern automotive design. By utilizing state-of-the-art technology, custom CNC machine automotive parts are crafted to perfection, ensuring an unmatched level of quality. Đây là thỏa thuận—with custom parts, manufacturers can meet the specific needs of their clients, deliver enhanced performance, and create long-lasting products that stand the test of time.

1. What is CNC Machining?

Definition and Basic Principles of CNC Machining

CNC (Computer Numerical Control) machining refers to a process in which machines are controlled by computers to manufacture parts with high precision. CNC machines interpret a digital file, such as a 3D model, and translate it into specific movements that shape raw material into a finished part. Bạn có thể đang thắc mắc, how does this all work? Well, it’s as simple as feeding the right code into a machine, and the machine does the rest. This allows for high efficiency and consistency, which is crucial when manufacturing automotive parts that require exact measurements.

How CNC Machining Differs from Manual Machining

Manual machining requires an operator to perform each step of the manufacturing process manually. While this can work for small, simple parts, it lacks the precision and consistency offered by CNC machining. CNC machines, on the other hand, can repeat the exact same operation multiple times, ensuring uniformity across large production runs. This is why CNC machining is preferred for custom automotive parts, where precision is a must.

2. The Importance of Customization in Automotive Parts

Why Custom Parts Are Vital for Automotive Performance

Customization is key when it comes to automotive parts. Each vehicle is designed with specific requirements in mind—whether it’s for speed, handling, or durability. Đây là thỏa thuận, custom CNC machined parts provide the perfect solution to meet these exact requirements. Unlike mass-produced parts, custom solutions can be designed to fit perfectly within the specific parameters of a vehicle, resulting in better overall performance.

Benefits of Customization in Terms of Performance and Longevity

When it comes to parts like engine components, suspension elements, and transmission systems, the benefits of custom CNC machining become immediately apparent. Custom parts can be tailored for increased strength, higher performance, and longer lifespan, all of which are critical to the longevity of the vehicle. Bạn có thể đang thắc mắc, what’s the impact on cost? While custom parts may have a higher initial cost, they often lead to savings down the road due to fewer replacements and repairs.

3. Materials Used in CNC Machining for Automotive Parts

Common Materials Used in CNC Machining for the Automotive Sector

CNC machining is highly versatile and can accommodate a wide variety of materials. In the automotive industry, metals such as aluminum, steel, and titanium are commonly used due to their strength and durability. Aluminum, for example, is lightweight, making it ideal for components where weight is a concern, such as in engines and suspension systems. Titanium, on the other hand, is known for its superior strength-to-weight ratio, making it perfect for high-performance parts.

Choosing the Right Material for Your Custom Parts

Selecting the right material for custom CNC machined parts depends on several factors, including the part’s function, environment, and desired properties. Đây là thỏa thuận, materials must be chosen carefully to ensure that the part performs optimally under stress, heat, and wear. For example, a component in the engine would require a different material than one used in the interior, as engine parts need to withstand higher temperatures and forces.

4. The CNC Machining Process: A Step-by-Step Breakdown

From CAD Design to the Final Product

The CNC machining process starts with a CAD (Thiết kế hỗ trợ máy tính) model. This digital blueprint contains every detail of the part, including dimensions, shapes, and tolerances. Bạn có thể đang thắc mắc, how do manufacturers turn a digital file into a physical part? The answer lies in the CNC machine. The design file is uploaded into the CNC machine, which uses specialized tools to cut, shape, and finish the part based on the digital model.

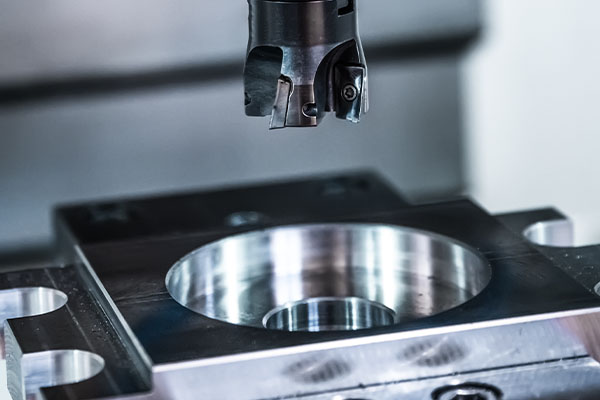

Cutting and Shaping Processes

Once the CAD design is in place, the CNC machine begins its work. Milling, drilling, turning, and other operations are carried out depending on the type of part and its complexity. Đây là thỏa thuận—CNC machining is capable of executing multiple cutting tasks in one cycle, ensuring both accuracy and speed in producing high-quality parts.

Quality Control and Inspection

No part leaves the factory without rigorous inspection. After the part is manufactured, it goes through a series of quality control checks. These ensure that the part meets the required tolerances, strength specifications, and overall functionality. For automotive parts, this is crucial as any small error can impact the vehicle’s performance or safety.

5. Common Automotive Parts Made with CNC Machining

Engine Components

CNC machining plays a major role in producing engine components such as pistons, crankshafts, and cylinder heads. These parts require extreme precision to ensure the engine runs smoothly. Bạn có thể đang thắc mắc, why is CNC machining preferred for such delicate parts? It’s simple—precision and durability are the foundation of these parts’ functionality, and CNC machining ensures both.

Transmission and Drivetrain Parts

Transmission parts like gears, shafts, and housings are another area where CNC machining excels. These parts are subjected to high levels of stress and need to be crafted to precise specifications. Đây là thỏa thuận, CNC machining allows manufacturers to achieve the necessary tolerances for these crucial components to function effectively.

Chassis and Suspension Parts

The suspension system, including control arms, shock mounts, and struts, requires custom parts to maintain vehicle stability. CNC machining ensures these parts are built to handle the stress of constant movement and weight distribution, contributing to overall vehicle safety.

Brake and Steering Components

Brake calipers, rotors, and steering knuckles are other essential parts in automotive systems that require custom CNC machining. These components undergo high stress, making precision machining vital for their performance and safety.

6. Advantages of Using CNC Machining for Automotive Parts

Precision and Repeatability

CNC machining’s ability to consistently produce parts with the same level of precision is a huge advantage in the automotive sector. Đây là thỏa thuận, when it comes to manufacturing parts that fit perfectly within an assembly, consistency is critical. CNC machines ensure that every part meets the exact same specifications, which reduces the risk of errors and defects.

Cost-Effectiveness for Both Small and Large Production Runs

Bạn có thể đang thắc mắc, does CNC machining only work for large production runs? The beauty of CNC is that it’s just as effective for small, custom orders as it is for mass production. CNC machines can produce both large quantities and one-off custom parts with the same level of efficiency and accuracy, making it a cost-effective solution for many businesses.

Customization and Flexibility

With CNC machining, manufacturers can produce parts that are specifically tailored to the client’s needs. Đây là thỏa thuận, this flexibility ensures that parts can meet the most precise performance standards and even be adapted for future design changes.

Reduced Waste

CNC machining reduces material waste by utilizing precise cutting techniques. Bạn có thể đang thắc mắc, how does this impact cost? Reduced waste means lower material costs, and this translates into overall savings for manufacturers. This makes CNC machining not only efficient but environmentally friendly.

7. CNC Machining vs. Traditional Manufacturing Methods

When Is CNC Machining Better Than Casting or Forging?

While traditional manufacturing methods like casting or forging are still used in some industries, CNC machining offers several advantages. Đây là thỏa thuận, CNC machining allows for greater precision, which is crucial for custom automotive parts. While casting and forging can be less expensive for simple parts, they often lack the fine detail that CNC machining can provide.

Speed and Accuracy Comparison

CNC machining is faster and more accurate compared to traditional methods. Bạn có thể đang thắc mắc, why does this matter? In the automotive industry, speed and accuracy directly impact production timelines and product quality, making CNC machining the preferred choice for many manufacturers.

8. Challenges in Custom CNC Machining for Automotive Parts

Material Selection Challenges

Selecting the right material is critical to ensuring that the custom part performs as expected. Đây là thỏa thuận, if the wrong material is chosen, the part might not withstand the pressures of regular use, leading to failure. It’s crucial to select the correct material based on the part’s specific function.

Tolerance and Precision Issues

Bạn có thể đang thắc mắc, how do manufacturers handle extremely tight tolerances? CNC machining can achieve incredibly precise measurements, but it requires skilled operators and the right machinery. Đây là thỏa thuận, getting the perfect tolerance is one of the most challenging aspects of producing custom automotive parts, and it’s essential for ensuring quality.

Cost Considerations for Custom Parts

Custom parts come with a higher upfront cost due to their bespoke nature and the additional time required for production. However, you might be wondering, are these costs justified? In many cases, yes. Custom parts often result in improved performance and longer-lasting components, which saves money in the long run.

9. The Role of 3D Printing in CNC Machining

How 3D Printing Complements CNC Machining

3D printing has become a valuable tool in the automotive industry for prototyping and creating complex designs. Bạn có thể đang thắc mắc, what’s the role of 3D printing in CNC machining? It allows manufacturers to quickly create prototypes before moving to full-scale CNC production. This combination speeds up the design process and reduces errors.

Benefits of 3D Printing in CNC

3D printing can be used to make prototypes, tooling, and even parts that are later refined using CNC machining. Đây là thỏa thuận, it allows manufacturers to test designs before investing in full-scale production, which can save both time and money.

10. Choosing the Right CNC Machine Shop for Automotive Parts

Factors to Consider When Selecting a CNC Machine Shop

When choosing a CNC machine shop, several factors must be considered, including the shop’s experience with automotive parts and its ability to meet specific design and performance requirements. Bạn có thể đang thắc mắc, how do I know if a shop is right for my project? Look for shops that specialize in automotive parts and have a reputation for precision and reliability.

How to Ensure Quality Control and Reliability

To ensure that parts meet the highest standards, look for machine shops that use the latest technology and have robust quality control processes in place. Đây là thỏa thuận, the best shops not only focus on delivering precise parts but also provide strong customer support and post-production services.

11. CNC Machining for Electric Vehicles (EVs)

Special Considerations for EV Components

Electric vehicles (EVs) have unique requirements when it comes to custom parts. For example, EVs require lightweight materials and highly efficient systems to maximize energy efficiency. Bạn có thể đang thắc mắc, what makes CNC machining perfect for EVs? The technology allows for the production of lightweight yet durable components, such as battery housings and motor mounts.

How Custom CNC Parts Improve EV Efficiency

By using custom CNC machined parts, EV manufacturers can optimize vehicle performance and efficiency. Đây là thỏa thuận, every part—from the battery pack to the transmission system—must be lightweight and highly durable to ensure maximum range and reliability. CNC machining helps achieve these goals by allowing for the precise crafting of parts tailored specifically to each vehicle’s needs.

12. The Future of Custom CNC Machining in the Automotive Industry

Emerging Technologies and Innovations

The future of CNC machining in the automotive industry looks bright, with several emerging technologies on the horizon. Bạn có thể đang thắc mắc, what’s next for CNC machining? Advancements in automation, machine learning, and AI are revolutionizing the way parts are designed, tested, and manufactured. These technologies promise even greater precision and efficiency.

Sustainability Trends in CNC Machining for Automotive Parts

As environmental concerns grow, the automotive industry is focusing on sustainable manufacturing practices. Đây là thỏa thuận, CNC machining is inherently more sustainable than traditional methods due to its ability to reduce waste and use energy-efficient processes. In the future, we can expect even more environmentally friendly practices in CNC machining.

13. How to Maintain CNC Machined Automotive Parts

Routine Maintenance and Care for Longevity

Proper maintenance is essential for extending the lifespan of CNC machined automotive parts. Bạn có thể đang thắc mắc, what steps should be taken to maintain these parts? Regular inspections and cleaning are crucial for preventing wear and ensuring the parts continue to perform at their best. Routine checks should be done to ensure there are no signs of cracking, corrosion, or other damage.

Signs of Wear and When to Replace Parts

Even the most durable parts will eventually show signs of wear. Đây là thỏa thuận, if parts start to perform below expectations, it’s time to replace them. Paying attention to performance changes is key to avoiding unexpected breakdowns and maintaining vehicle safety.

14. Case Studies: Successful Custom CNC Automotive Parts

Real-World Examples of Custom Parts in Action

One of the best ways to understand the impact of custom CNC machined parts is by looking at case studies from real automotive manufacturers. For example, companies that have used CNC machining to produce custom engine components, transmission parts, or suspension systems often experience enhanced vehicle performance and longevity.

Benefits Experienced by Companies Using CNC Machining

The use of CNC machining has proven to be beneficial for many companies, improving not only the quality of their products but also their manufacturing efficiency. Đây là thỏa thuận, companies that embrace CNC machining often find that the upfront investment pays off in the form of better product performance, customer satisfaction, and cost savings in the long term.

15. Conclusion: Perfecting Automotive Parts with Custom CNC Machining

Summary of Key Points

In this article, we’ve explored the various aspects of custom CNC machining for automotive parts, from its importance in creating high-precision components to the benefits it offers in terms of customization and performance. Đây là thỏa thuận, CNC machining has revolutionized the way automotive parts are made, ensuring that every part meets the exact specifications needed for optimal vehicle performance.

The Future Outlook for Custom CNC Automotive Parts

The future of CNC machining in the automotive sector is bright, with continuous advancements in technology promising even greater efficiency and precision. Bạn có thể đang thắc mắc, how can you stay ahead of the competition? Embrace the future of manufacturing by investing in CNC machining for your custom automotive parts.

Call to Action

If you’re looking for precision-engineered automotive parts that meet your exact requirements, consider partnering with a reliable CNC machining service. Đây là thỏa thuận, custom CNC machining can take your automotive products to the next level.

Phần Câu hỏi thường gặp

What are the typical lead times for custom CNC automotive parts?

Lead times can vary depending on the complexity of the parts and the shop’s workload, but typically, custom CNC parts can be manufactured within 2-4 weeks.

Can CNC machining be used for high-performance racing parts?

Absolutely! CNC machining is perfect for high-performance parts that require extreme precision, which is especially important in racing.

What is the minimum order quantity for custom CNC machined automotive parts?

The minimum order quantity depends on the machine shop, but many shops are capable of handling both small and large runs. For small runs, one-off parts are often acceptable.

How do I get a quote for CNC machining services for automotive parts?

To receive an accurate quote, provide the machine shop with your part design (CAD files), material choice, and the quantity you need. This allows them to assess the complexity and cost of production.