Giới thiệu

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry, providing unmatched precision, efficiency, and customization options. This advanced technology allows businesses to produce complex parts and components with high accuracy, making it indispensable in modern production. From the automotive to aerospace industries, CNC machining solutions have transformed how manufacturers approach production, lowering costs, increasing efficiency, and opening the door to high-quality custom solutions. In this article, we will explore how CNC machining is reshaping industries, its benefits, and why it’s a critical tool for businesses seeking to stay competitive in today’s fast-paced world.

1. The Basics of CNC Machining: Understanding the Process

How does CNC machining work?

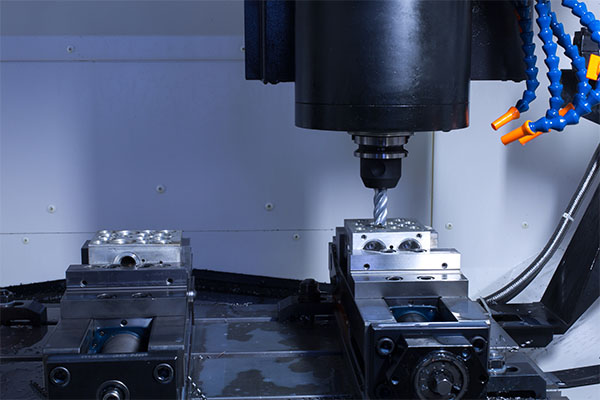

CNC machining is a manufacturing process that involves using computers to control machine tools such as mills, lathes, routers, and grinders. These machines operate on a digital file, typically created using CAD (Computer-Aided Design) software. CNC machines follow a set of precise instructions to carry out the manufacturing tasks, from drilling holes to cutting intricate shapes. The core principle is automation, which enables the production of highly accurate parts with minimal human intervention.

The process begins by creating a 3D digital design of the part to be produced. This design is then converted into a machine-readable format using CAM (Computer-Aided Manufacturing) software. The CNC machine follows these instructions, using rotating tools or fixed cutters to shape the material according to the design. Once the process is completed, the part is inspected for quality and precision.

What are the key components of CNC machining?

CNC machining involves several key components that work together to produce the final product. These include the machine itself, which can vary in type depending on the task (e.g., milling machine, lathe, or router); the CNC controller, which is the brain of the operation, sending commands to the machine; and the tooling, which performs the actual cutting, shaping, or drilling. The raw materials, such as metals, plastics, or composites, are also crucial in determining the capabilities and quality of the final product.

2. Types of CNC Machines and Their Applications

Máy phay CNC

CNC milling machines are used to cut, shape, and modify materials through a rotating cutter. They are highly versatile and can produce parts with intricate details. Milling machines are commonly used in industries like automotive, aerospace, and consumer electronics, where precision and customization are essential. These machines can produce everything from engine components to circuit board parts.

Máy tiện CNC

CNC lathes are primarily used for turning cylindrical parts. They use a rotating piece of material, which is cut or shaped by stationary tools. Lathes are perfect for creating parts with circular symmetry, such as shafts, bolts, and fittings. Industries that rely on CNC lathes include medical device manufacturing, automotive production, and even jewelry making.

Máy phay CNC

CNC routers are often used for cutting and shaping softer materials like wood, plastic, and foam. They use a rotating spindle to cut out intricate shapes and designs. Routers are commonly employed in industries like woodworking, signage, and furniture manufacturing, where large-scale cuts and customized designs are needed.

Other CNC Machines

In addition to milling machines, lathes, and routers, there are various other CNC machines that serve different purposes. CNC grinders, for example, are used to smooth and finish parts with high precision. Electrical Discharge Machines (EDM) are used to cut through hard materials, making them ideal for producing complex, fine features in materials like steel. CNC 3D printers are also emerging as an innovative solution for rapid prototyping and small production runs.

3. Key Advantages of CNC Machining

Precision and accuracy in production

One of the main benefits of CNC machining is its ability to produce highly accurate and precise parts. With tolerance levels often in the micrometer range, CNC machines can create parts that are nearly identical to the original design, down to the smallest detail. This precision is critical in industries like aerospace and medical device manufacturing, where even the slightest deviation can compromise safety or performance.

Speed and efficiency

Đây là thỏa thuận—CNC machines can work around the clock, reducing the production time significantly. Unlike manual labor, CNC machines can operate continuously without needing breaks, resulting in faster turnaround times. Bạn có thể đang thắc mắc how this impacts overall production; well, the speed and automation reduce labor costs and enable manufacturers to meet high-demand requirements with ease.

Reduced human error

Here’s the thing: CNC machines minimize the likelihood of mistakes during production. Since the process is automated, human intervention is limited, and the risk of errors due to fatigue, miscommunication, or oversight is significantly reduced. This results in fewer defective parts, saving both time and money on rework.

Cost-effectiveness in the long run

Although the initial investment in CNC machines can be high, they pay for themselves over time. The reason is simple—they offer long-term cost savings by reducing labor costs, improving production efficiency, and minimizing material waste. These factors make CNC machining a cost-effective solution for both small businesses and large-scale manufacturers.

4. Industries Transformed by CNC Machining

Ngành công nghiệp ô tô

The automotive industry is one of the largest beneficiaries of CNC machining. Custom parts, engine components, and transmission systems are all produced using CNC technology. What does that mean for manufacturers? It means they can produce highly specialized parts at scale, ensuring reliability and safety in every vehicle. CNC machining is also used for rapid prototyping, enabling manufacturers to test and refine new designs faster.

Ngành hàng không vũ trụ

Aerospace manufacturers rely on CNC machining for parts that must meet stringent tolerances and safety standards. The precision provided by CNC machines ensures that components like turbine blades, brackets, and landing gear are manufactured to exact specifications, which is crucial in the aerospace sector. CNC machining also supports the production of lightweight, high-strength materials commonly used in aircraft.

Medical Device Manufacturing

CNC machining plays a crucial role in the medical device manufacturing industry, where precision is paramount. Parts like surgical instruments, implants, and diagnostic equipment require high accuracy and quality. CNC machines allow manufacturers to produce these components efficiently, ensuring the highest standards of safety and performance in medical devices.

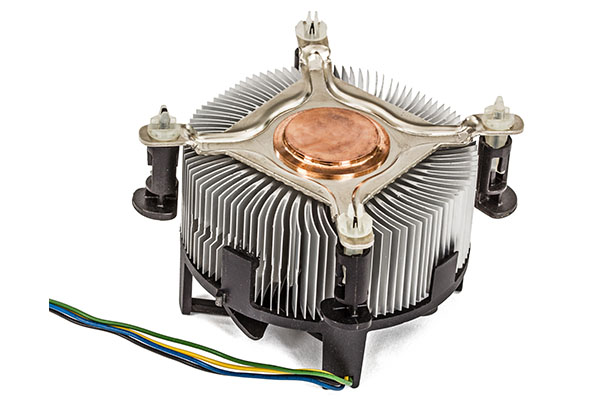

Electronics Industry

You might be surprised to learn that CNC machining is also widely used in the electronics industry. It’s used to create components such as connectors, circuit boards, and enclosures. These parts must be produced with fine details and high precision to ensure they function correctly and fit within the tight spaces of electronic devices.

Tool and Die Manufacturing

CNC machines are invaluable in the production of tools and dies used in other manufacturing processes. Here’s the thing: tools and dies need to be made with extreme precision to ensure they last and perform well over time. CNC machining meets these requirements by providing accurate and repeatable manufacturing processes that are ideal for toolmakers.

5. CNC Machining vs Traditional Manufacturing Methods

What are the key differences between CNC and traditional machining?

Here’s the key difference—traditional machining relies heavily on manual labor and skill, while CNC machining uses automated processes controlled by computer programs. CNC machines are capable of working with complex shapes and materials that would be difficult or impossible for a manual machine to handle. Additionally, CNC machining offers higher accuracy and consistency, making it ideal for mass production.

When is traditional machining still preferred?

While CNC machining offers several advantages, traditional machining still has its place, particularly in small shops or for simpler tasks. If you’re working with smaller quantities, traditional machining may be more cost-effective due to the lower upfront costs. It’s also suitable when dealing with materials or designs that don’t require the advanced precision CNC machines offer.

6. The Role of CNC in Custom Manufacturing

Custom and low-volume production with CNC

One of the most exciting benefits of CNC machining is its ability to handle custom and low-volume production. What does this mean for manufacturers? It means they can create one-off products, prototypes, or small batches without the need for expensive molds or tooling. CNC machines can easily switch between different designs, making them perfect for businesses that require a high level of customization.

How does CNC handle complex geometries and intricate designs?

Here’s the thing: CNC machines are capable of producing highly intricate and complex designs that would be impossible with traditional methods. By using advanced CAD software, manufacturers can design parts with intricate geometries that are then easily reproduced by the CNC machine. Whether it’s tiny gears, curving surfaces, or fine details, CNC machining handles it all with precision.

7. Automation and Its Role in CNC Machining

How does automation integrate with CNC machines?

Automation plays a pivotal role in CNC machining. Bạn có thể đang thắc mắc how automation fits into CNC machines; well, automation systems can integrate with CNC machines to handle material loading, part removal, and even quality inspections. These systems increase the efficiency of the manufacturing process, reducing downtime and labor costs while improving throughput.

What are the benefits of fully automated CNC machining?

Đây là thỏa thuận—fully automated CNC machining systems allow businesses to operate 24/7, reducing the need for human labor and increasing production speed. These systems also incorporate sensors and cameras to monitor the quality of each part, ensuring that defects are detected early and minimizing waste.

8. The Role of Software in CNC Machining

What is CAM (Computer-Aided Manufacturing) software?

CAM software is essential for converting digital designs into machine-readable code that controls the CNC machine. The key benefit here is that CAM software allows for the design and modification of parts in real time, enabling manufacturers to optimize production processes. This software is especially useful for producing complex parts that require detailed programming.

How does CAD (Computer-Aided Design) support CNC machining?

Here’s the thing: CAD software allows designers to create digital models of parts before they are physically produced. Why does this matter? Because CAD files are directly integrated with CNC machines, ensuring that the final product matches the design exactly. CAD software provides designers with a platform for precise modeling, making it easier to visualize and correct any design issues before machining.

9. The Impact of CNC Machining on Sustainability

How does CNC machining contribute to more sustainable manufacturing?

CNC machining is more sustainable than traditional manufacturing methods in several ways. Đây là thỏa thuận—CNC machines produce less waste by optimizing material usage. The precise cutting capabilities of CNC machines minimize off-cuts, and automation reduces the need for excess material. Additionally, the energy efficiency of modern CNC machines means lower environmental impact compared to traditional processes.

Are CNC machines environmentally friendly?

Bạn có thể ngạc nhiên to learn that CNC machines can be eco-friendly. Many CNC systems are designed to be energy-efficient, and their precise cutting reduces the need for rework, which can generate excess waste. By using less material and requiring fewer resources, CNC machining contributes to reducing the environmental footprint of manufacturing.

10. Challenges in CNC Machining

What are the common challenges in CNC machining?

Here’s the truth—CNC machining is not without its challenges. One of the biggest issues is the high upfront cost of equipment, which can be a significant investment for small businesses. Another challenge is the need for skilled operators who can program and maintain these machines. Additionally, CNC machines can be prone to wear and tear, which can affect their precision over time.

How do manufacturers overcome these challenges?

The key to overcoming these challenges lies in regular maintenance and investing in training for employees. Predictive maintenance technologies can help identify when machines are likely to fail, minimizing downtime. Additionally, investing in high-quality machines and tools can extend the lifespan and efficiency of CNC machines.

11. The Future of CNC Machining

What are the emerging trends in CNC machining?

CNC machining is evolving rapidly with the integration of Industry 4.0 technologies. Bạn có thể đang thắc mắc what that means for the future; well, it means smarter machines that can communicate with each other and analyze data in real time. What does this mean for manufacturers? It means greater efficiency, better quality control, and the ability to predict and prevent failures before they happen.

How will AI and robotics revolutionize CNC machining?

Artificial intelligence and robotics are set to revolutionize CNC machining by automating even more aspects of the process. Imagine this: AI will be able to analyze machine data, identify inefficiencies, and make adjustments in real-time to improve performance. Robotics will handle tasks like material loading, part sorting, and quality inspection, making the process even faster and more accurate.

12. CNC Machining for Small and Medium Enterprises (SMEs)

Can SMEs afford CNC machining?

CNC machining is becoming more accessible to SMEs due to advancements in technology and the availability of smaller, more affordable machines. Đây là thỏa thuận—while the initial cost of a CNC machine can still be high, smaller businesses can now find more cost-effective options. These machines provide flexibility, precision, and speed, which can make a significant difference in production efficiency and product quality.

How can SMEs take advantage of CNC technologies?

SMEs can leverage CNC technologies to streamline production, reduce costs, and offer customized products. What does this mean for small businesses? It means they can compete with larger manufacturers by offering precision, quick turnaround times, and innovative designs. CNC also allows for rapid prototyping, enabling small businesses to test new products without the high costs of traditional methods.

13. CNC Machining and Quality Control

How does CNC machining improve quality control?

Here’s the thing—CNC machining improves quality control by ensuring that parts are produced consistently and within tight tolerances. The automated nature of CNC machines reduces human error, while real-time monitoring and feedback loops ensure that each part meets the required specifications. Bạn có thể ngạc nhiên that CNC machines also have built-in error detection systems that identify potential issues before they escalate.

What are the standards and certifications for CNC machining?

To ensure quality, CNC machining is often performed under strict standards and certifications, such as ISO 9001. What does this mean for you? It means that manufacturers who follow these standards ensure that their parts meet the highest quality benchmarks, which is especially important in sectors like aerospace, medical devices, and automotive.

14. CNC Machining and Safety Considerations

What safety measures are required in CNC machining?

Đây là thỏa thuận—CNC machining is a safe process, but it requires adherence to safety protocols. Bạn có thể đang thắc mắc what those protocols are. Key safety measures include training operators, proper machine guarding, and regular maintenance. Ensuring the safety of CNC operators is essential for preventing accidents and maintaining a safe working environment.

How does CNC machining reduce workplace accidents?

By automating many aspects of the production process, CNC machining reduces the amount of manual handling required. This minimizes the risk of accidents, as workers are less likely to be exposed to dangerous cutting tools or high-speed moving parts. Additionally, CNC systems often include safety features such as emergency stops and protective enclosures.

15. Conclusion

CNC machining has fundamentally changed the manufacturing landscape. The bottom line is that it offers unparalleled precision, speed, and versatility, transforming industries ranging from automotive to aerospace. What does that mean for businesses? It means they can produce high-quality products faster, with fewer errors, and at a lower cost. CNC technology also provides opportunities for customization, allowing businesses to meet specific customer needs while staying competitive in the market.

Here’s the takeaway—if you’re looking to streamline your manufacturing processes, reduce costs, and improve product quality, CNC machining is the solution you need. Whether you’re a large manufacturer or a small business, CNC technology can provide the tools you need to succeed in an increasingly competitive marketplace.

Phần Câu hỏi thường gặp

What are the most common materials used in CNC machining?

Common materials include metals like aluminum, steel, and titanium, as well as plastics and composites. These materials are chosen based on the specific requirements of the part being produced.

How much does it cost to invest in CNC machining?

The cost varies depending on the type of machine, its capabilities, and the complexity of the parts being produced. Generally, an entry-level CNC machine can cost anywhere from $10,000 to $50,000, while high-end models can go for several hundred thousand dollars.

Can CNC machining be used for prototyping?

Yes, CNC machining is ideal for rapid prototyping. Why? Because it allows for quick, precise production of prototypes without the need for expensive molds or tooling.

What are the best CNC machines for small businesses?

Smaller businesses often opt for desktop CNC mills or routers that are more affordable yet still capable of handling small-scale production. These machines can be used for prototypes, custom products, and small batches.

How accurate is CNC machining?

CNC machining is highly accurate, often achieving tolerances as tight as 0.001 inches. This makes it perfect for industries that require precise and repeatable parts.