Introduction

CNC machining is an essential process in the manufacturing world, used to create high-precision parts from a variety of materials. One of the most common materials used for CNC machining is steel, but aluminum has also gained significant popularity due to its unique properties. Understanding the differences between CNC machining steel and aluminum is crucial for manufacturers to choose the best material for their projects. In this article, we will explore the key differences between CNC machining steel and aluminum, providing insight into their properties, machining processes, costs, and more.

1. What Are CNC Machining and Its Applications?

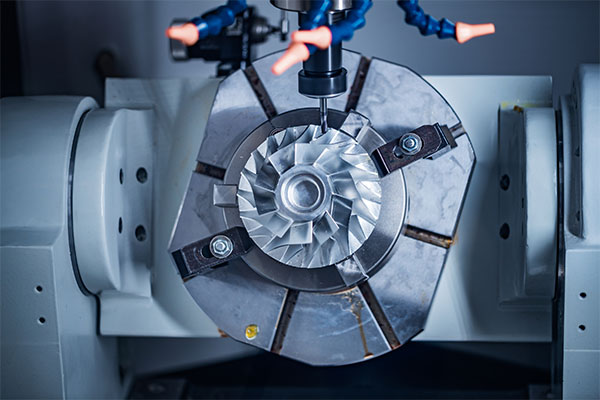

CNC machining is a manufacturing process in which a computer controls machine tools to precisely remove material from a workpiece, creating the desired shape. This process allows for high accuracy and the production of complex parts with tight tolerances. CNC machining can be used for a wide range of applications across various industries, including aerospace, automotive, medical devices, electronics, and more.

The primary goal of CNC machining is to produce precise and repeatable parts. In industries like aerospace, where even a fraction of a millimeter matters, CNC machining ensures that components meet the required specifications. Additionally, CNC machining can be performed on various materials, such as metals, plastics, and composites, making it a versatile option for manufacturers.

2. What is Steel and How Is It Used in CNC Machining?

Steel is one of the most commonly used materials in CNC machining. It is a versatile material that offers high strength, durability, and resistance to wear and tear. Steel is commonly used in manufacturing parts that require high strength and toughness, such as gears, shafts, and structural components.

There are various types of steel, including carbon steel, alloy steel, and stainless steel, each offering different properties suited to specific applications. For example, stainless steel is commonly used in applications where corrosion resistance is crucial, while carbon steel is often used for its strength and cost-effectiveness.

In CNC machining, steel requires precise cutting tools and careful control of machining parameters due to its toughness and hardness. Steel parts are often used in industries like construction, automotive, and manufacturing, where durability and strength are critical.

3. What is Aluminum and How Is It Used in CNC Machining?

Aluminum is another popular material in CNC machining due to its lightweight nature, corrosion resistance, and ease of machinability. Aluminum is commonly used in applications where weight reduction is a key factor, such as in the aerospace and automotive industries. Its low density makes it an excellent choice for parts that need to be strong yet lightweight.

There are various types of aluminum alloys, including 6061, 7075, and 2024, each offering different levels of strength, hardness, and corrosion resistance. For example, 6061 aluminum is often used for structural components, while 7075 aluminum is used in high-stress applications due to its superior strength-to-weight ratio.

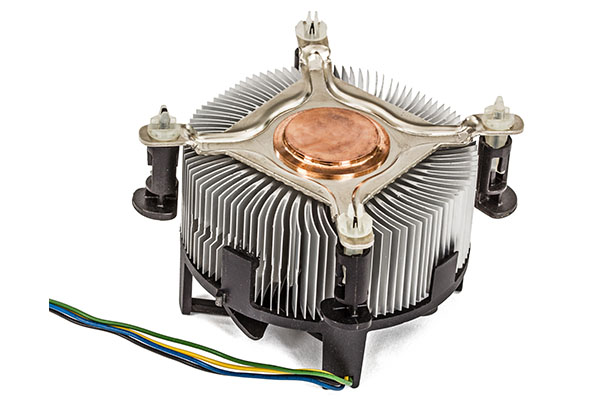

Aluminum is easier to machine than steel, which allows for faster processing times and less tool wear. It also tends to have better thermal conductivity, making it an ideal material for heat-sensitive applications like heat exchangers and electronic housings.

4. What Are the Key Differences Between CNC Machining Steel and Aluminum?

The primary differences between CNC machining steel and aluminum lie in their material properties and how they affect the machining process. Steel is stronger and harder than aluminum, which can make it more challenging to machine. The higher hardness of steel means that it requires slower machining speeds and more robust tooling to prevent excessive wear on the tools.

On the other hand, aluminum is softer and lighter, which allows it to be machined at faster speeds with less risk of tool wear. This can lead to quicker production times and lower costs for manufacturers. Aluminum also has better corrosion resistance, making it ideal for parts exposed to harsh environments.

5. How Does the CNC Machining Process Differ for Steel and Aluminum?

The CNC machining process for steel and aluminum differs in several key areas. For steel, slower cutting speeds are often required to prevent excessive heat buildup, which could damage the material and tools. Steel also requires high-strength cutting tools to handle its hardness and toughness.

In contrast, aluminum can be machined at faster speeds, allowing for shorter cycle times and increased productivity. Aluminum also requires less force to machine, which can reduce the wear on cutting tools and result in longer tool life.

When machining aluminum, it’s essential to use the right lubricants and coolants to prevent the material from sticking to the tools and causing poor surface finishes. Steel, due to its hardness, often requires more aggressive cooling methods to maintain tool longevity.

6. Why is Steel More Difficult to Machine Than Aluminum?

Steel is generally more difficult to machine than aluminum due to its higher hardness and toughness. These properties make it harder to cut, requiring stronger and more durable tooling. Steel also generates more heat during machining, which can lead to tool wear and deformation of the material if not properly managed.

Additionally, steel is more prone to work hardening, which occurs when the material becomes harder as it is machined. This can make it more difficult to cut through the material as the machining process progresses, requiring more careful adjustments to the cutting parameters.

7. Why is Aluminum Considered Easier to Machine Than Steel?

Aluminum is considered easier to machine than steel for several reasons. First, aluminum is softer and lighter, which means it requires less force to cut. This leads to faster machining speeds and less wear on cutting tools, resulting in longer tool life and lower operational costs.

Aluminum also has a lower melting point than steel, which reduces the risk of tool damage due to heat buildup. Its low density makes it easier to move during machining, allowing for quicker cycle times and higher throughput in production.

8. How Do the Surface Finishes of Steel and Aluminum Differ?

The surface finishes of steel and aluminum differ due to their material properties. Steel tends to have a rougher surface finish due to its hardness and tendency to generate more heat during machining. This can require additional finishing processes, such as polishing or coating, to achieve a smooth surface.

Aluminum, on the other hand, can achieve a smoother surface finish more easily due to its softness and lower heat generation during machining. This makes aluminum an ideal material for applications where surface appearance is important, such as in consumer products and decorative components.

9. What Are the Cost Differences Between Machining Steel and Aluminum?

The cost of machining steel and aluminum can vary significantly depending on the specific type of material and the machining process used. Generally, aluminum is more expensive than steel per unit of material, but the overall cost of machining aluminum may be lower due to faster machining speeds and less tool wear.

Steel, being harder and more durable, requires slower machining speeds, which can increase labor and tooling costs. Additionally, steel often requires more cooling and lubrication to prevent overheating, which can further increase operational costs.

10. How Does Material Selection Affect the Durability of CNC Machined Parts?

Material selection plays a significant role in the durability of CNC machined parts. Steel, with its higher strength and toughness, is often chosen for applications that require long-lasting performance under heavy loads and harsh conditions. Steel parts are more resistant to wear and deformation, making them ideal for high-stress applications like gears and bearings.

Aluminum, while not as strong as steel, offers excellent corrosion resistance and is ideal for applications where weight reduction is a priority. Aluminum parts are commonly used in the aerospace and automotive industries, where lightweight and durable components are essential.

11. What Are the Environmental Impacts of CNC Machining Steel vs Aluminum?

The environmental impacts of CNC machining steel and aluminum can differ based on several factors, including energy consumption, waste generation, and recycling rates. Steel is more energy-intensive to produce and recycle, which can increase its environmental footprint.

Aluminum, on the other hand, is highly recyclable and can be reused multiple times with minimal loss of material properties. Recycling aluminum requires less energy than producing new aluminum, making it a more environmentally friendly option.

Both materials have their environmental advantages and drawbacks, but choosing aluminum for certain applications can contribute to reducing the overall environmental impact of manufacturing processes.

12. How Can You Optimize the CNC Machining Process for Steel and Aluminum?

To optimize the CNC machining process for steel and aluminum, manufacturers should focus on adjusting machining parameters such as cutting speed, feed rate, and tool selection. For steel, using the right cutting tools and coolants is essential to maintaining efficiency and minimizing tool wear.

For aluminum, machining at higher speeds can improve productivity, but it’s important to ensure that the right lubrication and cooling methods are used to prevent material sticking and poor surface finishes. Regular maintenance and tool monitoring can also help improve the longevity of cutting tools and reduce operational costs.

13. When Should You Choose Steel Over Aluminum in CNC Machining?

Steel is the material of choice when strength, durability, and toughness are critical. Steel is commonly used in applications where the parts will be subjected to high stress, heavy loads, or extreme conditions, such as in the automotive and aerospace industries.

If the part needs to withstand wear, corrosion, or extreme temperatures, steel is often the better choice. Steel is also ideal for applications where precision and durability are paramount, such as in industrial machinery or construction equipment.

14. When Should You Choose Aluminum Over Steel in CNC Machining?

Aluminum is the preferred material when weight reduction is important. It is often chosen for parts that need to be strong but lightweight, such as in the aerospace, automotive, and electronics industries. Aluminum is also ideal for applications where corrosion resistance is essential, as it naturally forms a protective oxide layer that prevents corrosion.

Aluminum’s excellent machinability and faster processing speeds make it the better option when quick turnaround times and cost savings are a priority.

15. How Do Steel and Aluminum Machining Compare for Custom Orders?

When it comes to custom orders, both steel and aluminum have their advantages and drawbacks. Steel is often the better choice for custom orders requiring high strength and durability, while aluminum is more suitable for custom parts that prioritize weight reduction and corrosion resistance.

Steel custom parts may take longer to machine due to the slower machining speeds, but they offer superior performance in demanding applications. Aluminum custom parts, on the other hand, can be produced faster and at a lower cost, making them ideal for projects with tight deadlines or budget constraints.

Conclusion

In conclusion, understanding the differences between CNC machining steel and aluminum is crucial for manufacturers looking to optimize their production processes. Steel offers higher strength and durability, making it ideal for heavy-duty applications, while aluminum is lighter and easier to machine, making it better for applications where weight reduction and corrosion resistance are important. By carefully considering the material properties and machining requirements, manufacturers can choose the best material for their needs, optimizing both performance and cost.

FAQ Section

Q1: What is CNC machining?

CNC machining is a manufacturing process in which a computer controls machine tools to precisely remove material from a workpiece, creating custom parts or products.

Q2: How does CNC machining steel differ from machining aluminum?

Steel is tougher and harder to machine than aluminum, requiring more robust tooling and slower speeds. Aluminum, being lighter and softer, can be machined faster with less tool wear.

Q3: Is aluminum more expensive than steel for CNC machining?

Typically, aluminum is more expensive than steel per unit, but the overall machining costs for aluminum can be lower due to its easier machinability and faster processing speeds.

Q4: What are the benefits of using aluminum in CNC machining?

Aluminum is lightweight, corrosion-resistant, and provides excellent machinability, making it ideal for applications where weight reduction and durability are key factors.

Q5: Can you machine both steel and aluminum on the same CNC machine?

Yes, CNC machines can be used to machine both steel and aluminum, but different tool settings and cutting parameters are required for each material to achieve optimal results.