Introduction

CNC machining aluminum is a precise and efficient process used to manufacture parts and components from aluminum alloys. The process is widely used in industries such as aerospace, automotive, and electronics due to the material’s versatility, lightweight, and corrosion-resistant properties. In this article, we will explore the steps involved in CNC machining aluminum, the types of machines used, and the benefits and challenges associated with this manufacturing process. You will also gain insight into how to choose the right tools and machines for the job and how to ensure the quality of your finished products. But here’s the kicker—whether you are new to CNC machining or looking to improve your workflow, understanding the full process is key to optimizing your production line.

1. What is CNC Machining Aluminum?

CNC machining aluminum is the process of using computer-controlled machines to cut, shape, and finish aluminum parts with high precision. This process involves several techniques, including milling, turning, and drilling, which are controlled by a computer program that directs the machine to follow the designed specifications. The popularity of aluminum in CNC machining can be attributed to its desirable properties such as being lightweight, corrosion-resistant, and easy to machine. Aluminum is a soft material, making it ideal for high-precision manufacturing in a variety of applications.

Aluminum alloys are used in CNC machining because they offer an excellent balance of strength, weight, and durability. For instance, 6061 aluminum is one of the most commonly used alloys in CNC machining due to its ability to resist corrosion and its strength-to-weight ratio. With CNC machining, manufacturers can create complex and highly accurate parts that would be difficult or impossible to produce with traditional machining methods. The versatility of aluminum also allows for its use in many different industries, from aerospace and automotive to medical and consumer electronics. This is where it gets interesting—aluminum’s adaptability to various applications makes it an essential material in modern manufacturing.

Table 1: Common Aluminum Alloys Used in CNC Machining

| Alloy Type | Composition | Key Properties | Common Uses |

|---|---|---|---|

| 6061 | Al, Mg, Si | Good corrosion resistance, lightweight | Aerospace, automotive, marine |

| 7075 | Al, Zn, Mg | High strength, tough | Military, aerospace |

| 2024 | Al, Cu, Mg | Excellent fatigue resistance | Aircraft, military |

| 3003 | Al, Mn | Excellent corrosion resistance, medium strength | Roofing, siding, cooking utensils |

2. How Does CNC Machining Work for Aluminum?

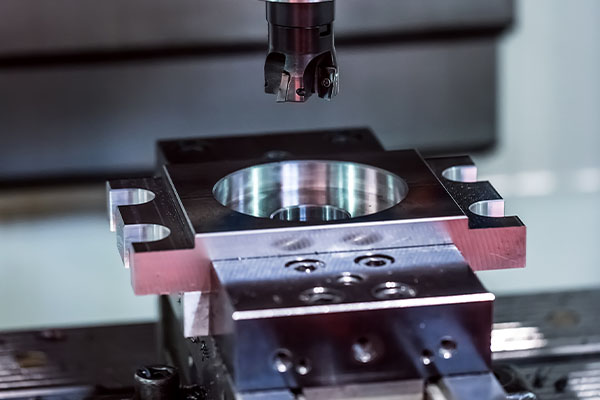

CNC machining for aluminum is controlled by computer programming that directs the machine to perform a series of precise operations to shape the material. The process begins with selecting the appropriate aluminum alloy based on the required strength, weight, and durability for the final product. Next, the aluminum stock is placed into the CNC machine, and the program is uploaded, dictating the necessary cuts and tool paths. The machine uses rotating cutting tools such as end mills, drills, and lathes to remove material and create the desired shape.

The key to successful CNC machining of aluminum lies in maintaining the right cutting conditions, such as speed, feed rates, and depth of cut. Aluminum has a low melting point compared to other metals, which can lead to issues like material buildup and excessive heat during machining. Therefore, it is crucial to use coolant systems to dissipate heat and prevent the material from distorting. The accuracy of CNC machines ensures that even the most complex shapes and detailed parts can be created with minimal material waste.

But here’s the kicker—when done correctly, CNC machining aluminum allows manufacturers to create parts that meet tight tolerances and high-quality standards, reducing the need for post-production processes like polishing and finishing.

Table 2: Key Factors in CNC Machining Aluminum

| Factor | Description |

|---|---|

| Cutting Speed | The rate at which the cutting tool moves along the material |

| Feed Rate | The speed at which the material is fed into the machine |

| Cutting Depth | The thickness of material removed per pass |

| Tool Selection | Type of cutting tool used (e.g., end mills, drills) |

| Cooling Method | Use of coolant to manage heat and prevent material distortion |

3. What Are the Key Steps in CNC Machining Aluminum?

The CNC machining process for aluminum involves several key steps that must be carefully executed to achieve the desired part. These steps ensure that the material is properly shaped and finished, meeting the necessary specifications.

The first step is preparation, where the aluminum stock is cut to the approximate size needed for the final part. This initial cut ensures that the material is the right shape and size for further machining. Next, the CNC machine is set up with the correct tooling and cutting parameters, including speed, feed rates, and cutting depth. After setting up the machine, the aluminum part is machined according to the programmed instructions, with each pass removing a small amount of material to reach the desired final dimensions.

Once the machining process is complete, the part undergoes a quality control check to ensure it meets the required specifications. This may involve visual inspection, dimensional measurements, and other tests depending on the part’s intended use. Finally, the part is cleaned, deburred, and finished to remove any sharp edges or surface imperfections.

Table 3: CNC Machining Process Steps

| Step | Description |

|---|---|

| Material Preparation | Cut aluminum stock to size and shape for machining |

| Machine Setup | Install correct tooling, set cutting parameters |

| Machining | Perform cuts to achieve final dimensions |

| Quality Control | Inspect part for tolerances and specifications |

| Finishing | Deburr, clean, and finish the part as required |

4. What Types of CNC Machines Are Used for Aluminum?

CNC machines come in different types and configurations, each suited to specific tasks in aluminum machining. The most common types used for aluminum machining are CNC mills, CNC lathes, and CNC routers.

CNC mills are the most versatile machines and are capable of performing a wide range of operations, such as drilling, milling, and boring. They are ideal for machining aluminum parts that require complex shapes and precision. CNC lathes, on the other hand, are used for turning operations, where the material is rotated while a cutting tool is applied to remove material. CNC routers are typically used for larger aluminum parts, particularly in the woodworking and sign-making industries, although they can also handle aluminum machining for simpler tasks.

Choosing the right CNC machine for aluminum depends on the specific requirements of the part being produced, including the complexity of the design and the level of precision needed. What’s the real story? When selecting a machine, it’s crucial to consider factors such as part geometry, material thickness, and production volume.

Table 4: Types of CNC Machines for Aluminum

| Machine Type | Ideal for | Common Operations |

|---|---|---|

| CNC Mill | Complex part shapes and precision work | Drilling, milling, boring |

| CNC Lathe | Rotational parts and cylindrical machining | Turning, facing, threading |

| CNC Router | Large parts or high-volume production | Cutting, engraving |

5. Why is Aluminum a Popular Choice for CNC Machining?

Aluminum’s popularity in CNC machining stems from its excellent combination of properties that make it ideal for a variety of applications. One of its main advantages is its lightweight nature, which makes it easier to handle and reduces the overall weight of finished parts. Aluminum is also highly resistant to corrosion, especially when anodized, which is an important consideration for parts used in harsh environments.

Another significant advantage of aluminum is its ease of machining. Unlike steel, which can be difficult to machine without specialized tools and techniques, aluminum is soft enough to allow for faster machining without compromising tool life. This makes aluminum an attractive option for manufacturers looking to produce large quantities of parts quickly and cost-effectively. Ready for the good part? The strength-to-weight ratio of aluminum means that it can be used in a wide range of industries, from aerospace and automotive to medical devices and electronics.

Table 5: Benefits of CNC Machining Aluminum

| Benefit | Description |

|---|---|

| Lightweight | Reduces overall part weight, improving performance |

| Corrosion Resistance | Resists rust and degradation, especially when anodized |

| Ease of Machining | Faster machining compared to harder materials like steel |

| Versatility | Suitable for various industries and applications |

6. What Are the Benefits of CNC Machining Aluminum?

CNC machining aluminum offers several advantages, including precision, cost-effectiveness, and speed. One of the key benefits of using CNC machining for aluminum is the high level of accuracy that can be achieved. CNC machines can produce parts with very tight tolerances, which is critical in industries like aerospace, where even the smallest deviation can lead to failure.

Additionally, CNC machining aluminum is highly efficient. The process can be automated, which allows for high-volume production with minimal labor and human error. This leads to reduced costs and faster turnaround times. The ability to automate the process also means that aluminum parts can be produced in large batches, increasing efficiency and lowering per-unit costs.

Another advantage of CNC machining aluminum is the material’s ability to be used in a wide range of industries. Whether it’s in the aerospace, automotive, or medical fields, aluminum parts are integral to modern technology. So, what’s the catch? Despite its benefits, CNC machining aluminum can pose challenges, such as tool wear and heat buildup, which must be managed to maintain quality and efficiency.

Table 6: Advantages of CNC Machining Aluminum

| Advantage | Description |

|---|---|

| High Precision | Achieves tight tolerances with minimal variation |

| Speed and Efficiency | Faster production times due to automated processes |

| Cost-Effective | Lower per-unit costs when producing large quantities |

| Versatility | Ideal for multiple industries and applications |

7. What Are the Challenges of CNC Machining Aluminum?

While CNC machining aluminum has its benefits, there are also challenges that manufacturers must consider. One of the main challenges is managing tool wear. Aluminum is a soft material, but it can still cause tool wear over time, especially when machining at high speeds or with inappropriate tooling.

Another challenge is heat buildup. During machining, aluminum generates heat, which can lead to material distortion if not properly managed. This is why it’s important to use cooling systems, such as flood cooling or mist cooling, to dissipate the heat and maintain the integrity of the part. This is where it gets interesting—without proper cooling, the aluminum can warp or even crack, leading to defects in the final product.

Finally, achieving a smooth surface finish can also be difficult, especially when machining high-speed or high-volume parts. The rough surface left behind after machining may require additional finishing operations such as polishing or anodizing.

Table 7: Common CNC Machining Challenges for Aluminum

| Challenge | Solution |

|---|---|

| Tool Wear | Use carbide tools and maintain proper machine settings |

| Heat Buildup | Implement effective cooling methods like flood cooling |

| Surface Finish | Use polishing or anodizing to improve surface appearance |

Conclusion

In conclusion, CNC machining aluminum is an effective and versatile process used in a variety of industries. By understanding the different types of machines, the machining steps, and the benefits and challenges, manufacturers can optimize their operations to produce high-quality aluminum parts. Whether you are new to CNC machining or looking to improve your process, knowing the ins and outs of aluminum machining will give you the edge you need to succeed.

8. How Do You Choose the Right CNC Machine for Aluminum?

Choosing the right CNC machine for aluminum machining is critical to achieving the desired precision and efficiency. The decision depends on several factors, including the complexity of the part, the production volume, and the required tolerance.

Key Considerations:

● Part Geometry: Consider the complexity of the part design. For complex geometries, a multi-axis CNC mill is typically required, whereas simpler parts can be machined using basic lathes or routers.

● Machine Size: The size of the CNC machine should be matched to the size of the aluminum stock and the part’s required dimensions. Larger machines can handle bigger components and more detailed work.

● Machine Power: The power of the machine determines its cutting speed and ability to handle different aluminum alloys. Machines with more horsepower can handle larger parts and tougher cutting conditions.

● Speed and Precision: Faster CNC machines can help increase productivity, but they must still maintain high levels of accuracy for aluminum parts. Choose a machine that offers a balance between speed and precision for optimal results.

9. What Are the Best Cutting Tools for Aluminum?

The cutting tools used for CNC machining aluminum play a crucial role in determining the quality and efficiency of the process. Aluminum is a relatively soft material, but it can cause wear on tools over time. Therefore, selecting the right cutting tools is essential to minimize wear and maintain machining precision.

Types of Cutting Tools:

● Carbide Tools: Carbide cutting tools are ideal for aluminum machining due to their high hardness and wear resistance. They allow for faster cutting speeds while maintaining part quality.

● High-Speed Steel (HSS) Tools: While not as durable as carbide tools, HSS tools are still commonly used for aluminum due to their affordability and effectiveness for basic machining.

● Coated Tools: Tools coated with materials such as titanium nitride (TiN) or titanium carbonitride (TiCN) offer enhanced durability and reduced friction, prolonging tool life during aluminum machining.

● Specialized Tools: For aluminum, specialized tools such as carbide end mills and drills with sharp cutting edges and optimized geometries help achieve smoother finishes and faster cuts.

10. How Does CNC Machining Achieve Precision with Aluminum?

One of the main advantages of CNC machining is its ability to achieve exceptional precision, even with soft metals like aluminum. The precision of CNC machining for aluminum is achieved through a combination of advanced technology, accurate programming, and careful process control.

Techniques for Achieving Precision:

● Programmed Tool Paths: CNC programming involves creating detailed tool paths that direct the machine to make precise cuts. The accuracy of the program ensures that each cut is made to the exact specification.

● Machine Calibration: Proper calibration of the CNC machine ensures that each axis moves accurately and consistently, preventing errors in part dimensions.

● High-Quality Cutting Tools: The use of sharp, high-quality cutting tools minimizes errors and ensures smoother cuts. Dull tools can cause inaccuracies and surface imperfections.

● Cooling Systems: Effective cooling systems help to dissipate heat and maintain part stability, preventing distortion and ensuring accuracy throughout the machining process.

11. How Long Does It Take to CNC Machine Aluminum?

The time it takes to CNC machine aluminum depends on various factors, such as part complexity, machine type, cutting parameters, and batch size. However, in general, aluminum is a faster material to machine compared to other metals like steel or titanium due to its softness and machinability.

Factors That Affect Machining Time:

● Part Complexity: More intricate parts with fine details or multiple features will take longer to machine compared to simple shapes.

● Cutting Parameters: Speed, feed rate, and cutting depth all affect the time needed to complete a part. Adjusting these parameters can help optimize machining time.

● Material Thickness: Thicker aluminum materials take longer to cut, as more material needs to be removed.

● Machine Efficiency: Modern CNC machines with higher power and speed capabilities can complete machining tasks faster than older or less powerful machines.

12. What Industries Use CNC Machined Aluminum Parts?

CNC machining aluminum is a vital process for several industries that require lightweight, durable, and corrosion-resistant components. From aerospace to automotive, aluminum’s versatility makes it the preferred material in many manufacturing processes.

Key Industries:

● Aerospace: The aerospace industry uses aluminum for parts like engine components, fuselage frames, and landing gear due to its lightweight properties and strength.

● Automotive: In the automotive industry, aluminum is used for parts like engine blocks, wheels, and body panels, contributing to fuel efficiency and overall vehicle performance.

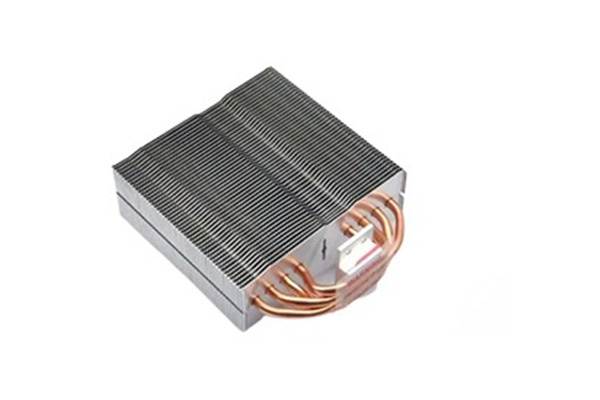

● Electronics: Aluminum is commonly used in the electronics industry for heat sinks, casings, and enclosures, as it provides excellent thermal conductivity and protects sensitive components.

● Medical Devices: Aluminum parts are used in medical equipment and devices, where lightweight and durability are essential. CNC machining ensures precise and sterile parts.

● Consumer Goods: Aluminum components in consumer products such as smartphones, kitchen appliances, and sporting goods are produced through CNC machining for strength and aesthetic appeal.

13. How Much Does CNC Machining Aluminum Cost?

The cost of CNC machining aluminum depends on several factors, including material costs, machine time, labor, and the complexity of the part being produced. Aluminum is generally more affordable to machine than other metals like titanium, but the final cost will vary depending on the job’s specifics.

Factors Affecting Cost:

● Material Cost: Aluminum alloys vary in price depending on their composition and availability. Some high-strength alloys may cost more than others.

● Machine Time: The longer it takes to machine a part, the higher the cost. Complex parts that require multiple machining steps will generally cost more.

● Tooling and Labor: Specialized cutting tools, setup time, and labor costs also contribute to the overall cost of the project.

● Production Volume: Larger production volumes generally reduce the per-unit cost, as the setup costs are spread across more parts.

14. How Do You Ensure Quality in CNC Machined Aluminum Parts?

Ensuring high-quality CNC machined aluminum parts requires thorough quality control throughout the entire manufacturing process. From selecting the right material to inspecting the finished part, every step must be carefully monitored to meet industry standards.

Quality Control Methods:

● Inspection and Measurement: Parts should be inspected using tools such as micrometers, calipers, and coordinate measuring machines (CMM) to ensure they meet the specified tolerances.

● Post-Machining Processes: Processes like deburring, polishing, and anodizing can improve the appearance and functionality of aluminum parts.

● Testing: Non-destructive testing methods such as X-ray or ultrasonic testing can be used to detect internal flaws in aluminum parts.

● Compliance with Standards: Adhering to industry standards and certifications, such as ISO 9001, ensures that parts meet quality and safety requirements.

15. How Can CNC Machining Aluminum Be Improved?

Continuous improvements in CNC machining technology help optimize the process for aluminum. By adopting new technologies and techniques, manufacturers can increase efficiency, reduce costs, and improve the quality of their parts.

Strategies for Improvement:

● Investing in Advanced CNC Machines: Newer machines offer faster processing speeds, greater precision, and more flexibility in part design.

● Automation: Incorporating automation into the machining process can reduce labor costs and increase production capacity.

● Improved Tooling: Developing cutting tools with enhanced wear resistance and thermal stability can help extend tool life and improve machining efficiency.

● Enhanced Cooling Systems: Upgrading cooling systems to manage heat more effectively can improve part quality and reduce material distortion during machining.

FAQ Section

Q1: What is CNC machining aluminum?

CNC machining aluminum involves using computer-controlled machines to cut, shape, and finish aluminum parts with precision. This process includes operations such as milling, drilling, and turning.

Q2: How does CNC machining work for aluminum?

CNC machining for aluminum involves feeding a computer program into a CNC machine that directs it to perform precise cuts and shapes, ensuring accuracy and consistency.

Q3: Why is aluminum a preferred material for CNC machining?

Aluminum is lightweight, corrosion-resistant, and easy to machine, making it ideal for producing parts in a variety of industries, including aerospace, automotive, and medical devices.

Q4: How long does it take to CNC machine aluminum?

The time it takes to CNC machine aluminum depends on factors such as part complexity, machine type, and production volume. Typically, aluminum can be machined faster than other metals due to its softness.

Q5: What industries use CNC machined aluminum parts?

CNC machined aluminum parts are widely used in industries such as aerospace, automotive, electronics, and medical devices, due to the material’s strength, lightness, and versatility.