Introduction

Aluminum CNC machining is a highly effective and precise manufacturing process used to create custom parts for a variety of industries. If you’re involved in manufacturing, engineering, or product development, understanding the advantages of aluminum CNC machining could significantly impact your business. In this article, we’ll explore why you need aluminum CNC machining, its benefits, applications, and how it can help you achieve precision and cost-efficiency in your production process. Let’s dive into the details to understand why this technology is becoming increasingly essential for businesses today.

1. Why Is Aluminum CNC Machining So Important?

Aluminum CNC machining is crucial for businesses seeking precision and cost-effectiveness in their manufacturing processes. But here’s the kicker—it’s not just about cost savings; it’s about quality and versatility. CNC (Computer Numerical Control) machining offers unmatched precision when working with aluminum, a lightweight yet durable metal. This is especially important when you need parts with tight tolerances or complex geometries that would be difficult to achieve through traditional methods.

The primary reason aluminum CNC machining is so important is its ability to create parts with exceptional accuracy. For industries like aerospace, automotive, and electronics, precision is non-negotiable. Additionally, aluminum’s inherent properties, such as its corrosion resistance and lightweight nature, make it an ideal material for a wide range of applications. Not to mention, aluminum parts are often less expensive to produce than other materials, making CNC machining a cost-effective option.

2. What Are the Advantages of Aluminum in CNC Machining?

Aluminum stands out as a preferred material for CNC machining due to its unique combination of properties. What’s the real story behind its widespread use in manufacturing? Let’s break it down.

● Lightweight: Aluminum is significantly lighter than other metals like steel, which makes it ideal for applications where weight reduction is a key factor, such as in aerospace or automotive components.

● Corrosion Resistance: Aluminum naturally forms an oxide layer that protects it from rust and corrosion, which makes it suitable for outdoor applications or parts exposed to harsh conditions.

● Ease of Machining: Aluminum is easier to machine compared to other metals like steel or titanium. This translates to faster production times and reduced wear on tooling, which ultimately lowers costs.

● Thermal and Electrical Conductivity: Aluminum has excellent thermal and electrical conductivity, making it a preferred choice for electronics and heat sinks.

3. How Does CNC Machining Work with Aluminum?

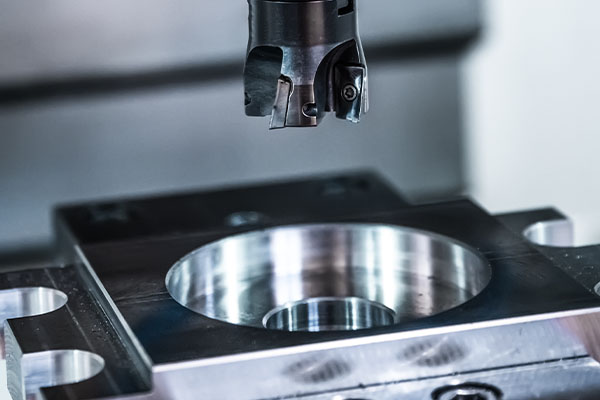

CNC machining works by using computer-controlled machines to precisely shape and cut material into specific designs. So, how does it work with aluminum? The process starts with a digital model created using CAD (Computer-Aided Design) software. This model is then fed into a CNC machine, which uses a variety of tools like mills, lathes, and drills to cut the aluminum into the desired shape.

One of the key benefits of CNC machining with aluminum is the ability to achieve very high levels of precision. The machines can work with tolerances as tight as a few microns, which is crucial for parts that require exact specifications, such as in the aerospace or medical industries.

Additionally, CNC machines use advanced tools that reduce the risk of human error and increase the overall consistency of parts. Whether you’re machining simple or complex shapes, CNC machining can deliver the results you need quickly and efficiently.

4. When Should You Consider Aluminum CNC Machining for Your Products?

So, when is aluminum CNC machining the right choice for your product? It’s not always the first option that comes to mind, but it’s one of the best solutions for many industries. Here are a few cases when you should consider using aluminum for CNC machining:

● For Lightweight Parts: If your product requires components that are strong yet lightweight, aluminum is an ideal material. For example, in the aerospace or automotive industries, parts need to be lightweight for fuel efficiency without sacrificing strength.

● For Precision Parts: When you need parts with very tight tolerances, aluminum CNC machining is a great choice. Industries that require high precision, such as electronics or medical devices, often turn to aluminum for its machinability and reliability.

● For Corrosion-Resistant Components: If your parts will be exposed to moisture, salt, or harsh chemicals, aluminum’s natural corrosion resistance makes it a reliable choice for outdoor or industrial applications.

5. What Are the Key Benefits of Using CNC Machining for Aluminum Parts?

Ready for the good part? Here are the key benefits that make aluminum CNC machining such a popular choice for manufacturers:

● Precision: CNC machining allows for the production of aluminum parts with extremely tight tolerances and high accuracy, which is critical in industries like aerospace and medical devices.

● Cost-Effective: While aluminum is a relatively inexpensive material, the use of CNC machining helps keep production costs low. The process minimizes material waste, reduces labor costs, and ensures faster turnaround times.

● Versatility: CNC machining can be used to create a wide range of aluminum parts, from simple shapes to complex geometries. Whether you need small components or large assemblies, aluminum CNC machining can handle it.

6. How Does Aluminum CNC Machining Ensure High-Quality Aluminum Parts?

But here’s the kicker—it’s all about the precision and control that CNC machining offers. The accuracy of the process ensures that every part meets the required specifications. When it comes to aluminum, achieving a high-quality finish is critical, especially for industries where aesthetics and function go hand in hand.

CNC machines are equipped with high-tech sensors that constantly monitor the machining process, ensuring that each part is produced to the correct dimensions. Additionally, advanced cooling systems help to prevent aluminum from overheating during the machining process, which could otherwise affect its properties.

Another factor that contributes to the high quality of CNC machined aluminum parts is the use of cutting-edge software that optimizes the machining path, ensuring that parts are cut with the least amount of material waste possible.

7. What Are the Common Applications of Aluminum CNC Machining?

Aluminum CNC machining is used in a wide variety of industries. So, where does it make the most impact?

● Aerospace: Aluminum is commonly used in the aerospace industry due to its lightweight properties. Components such as structural parts, frames, and engine components benefit from aluminum’s strength and low weight.

● Automotive: In the automotive industry, aluminum parts are used to reduce vehicle weight and improve fuel efficiency. From engine components to body parts, CNC machining plays a crucial role in producing precision aluminum parts.

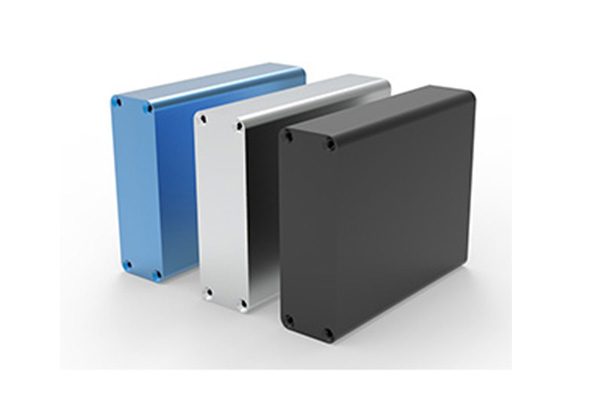

● Electronics: Many electronic devices, such as smartphones and laptops, use aluminum for their casings and components. CNC machining helps produce these parts with high accuracy and efficiency.

8. How Do You Choose the Right Aluminum Grade for CNC Machining?

Choosing the right aluminum grade for CNC machining can be a daunting task. It’s crucial to pick a grade that aligns with the specific needs of your project. The most common grades used in CNC machining are:

● 6061 Aluminum: Known for its good mechanical properties and weldability, 6061 is one of the most popular aluminum alloys for CNC machining.

● 7075 Aluminum: Stronger than 6061, 7075 is often used in high-stress applications like aerospace and military parts.

● 2024 Aluminum: This alloy is highly resistant to fatigue, making it ideal for aerospace applications.

When selecting the right grade, consider factors such as strength, corrosion resistance, machinability, and cost.

9. What Are the Challenges of Aluminum CNC Machining?

Every process has its challenges, and aluminum CNC machining is no different. Some of the common issues faced include:

● Tool Wear: Aluminum can be relatively soft, which can cause increased tool wear. However, using the right tools and maintaining them properly can reduce this problem.

● Heat Buildup: During machining, aluminum can heat up quickly, which can affect its properties. Ensuring proper cooling and ventilation is essential to avoid overheating.

● Surface Finish: Achieving a smooth surface finish on aluminum can be challenging. The use of fine cutting tools and proper post-machining treatments can help achieve the desired finish.

10. How Does Aluminum CNC Machining Compare to Other Machining Methods?

Here’s where it gets interesting—how does aluminum CNC machining stack up against other machining methods?

Compared to traditional machining methods like casting or forging, CNC machining offers more precise control and faster turnaround times. While other methods may be suitable for some applications, they often come with higher material waste and longer production times. CNC machining, on the other hand, is a more efficient and cost-effective solution for producing aluminum parts with tight tolerances and complex geometries.

11. Why Is CNC Machining Cost-Effective for Aluminum?

When you’re considering CNC machining for aluminum parts, cost-efficiency is a major factor. CNC machining minimizes material waste, reduces labor costs, and offers faster production cycles. This means you can get high-quality aluminum parts at a lower cost compared to traditional machining methods.

Additionally, aluminum is a relatively inexpensive material, and when paired with the precision of CNC machining, the overall cost of production becomes very competitive.

12. What Are the Environmental Benefits of Aluminum CNC Machining?

In today’s world, sustainability is more important than ever. The good news is that aluminum is one of the most recyclable materials available. CNC machining further contributes to environmental sustainability by minimizing material waste and energy consumption.

By optimizing the machining process and ensuring high precision, aluminum CNC machining helps reduce the amount of scrap produced during manufacturing. Furthermore, the long lifespan of aluminum parts reduces the need for frequent replacements, lowering overall waste.

13. How Can You Optimize Your Aluminum CNC Machining Process?

Optimizing your aluminum CNC machining process can lead to greater efficiency and reduced costs. Here are a few tips:

● Tool Maintenance: Regularly maintaining and replacing cutting tools can help improve performance and reduce tool wear.

● Use of Technology: Incorporating advanced CNC machines with automation and smart technology can enhance precision and reduce production time.

● Proper Cooling: Ensuring that proper cooling methods are in place will help manage heat buildup and maintain the quality of your aluminum parts.

14. What Are the Latest Trends in Aluminum CNC Machining?

CNC machining is constantly evolving, and several trends are shaping the future of aluminum machining:

● Automation: Automated CNC machines are improving speed and accuracy, reducing the need for human intervention.

● Additive Manufacturing: Hybrid machines that combine additive and subtractive processes are becoming more popular, offering new possibilities for aluminum parts.

● Smart Machining: Machine learning and AI are being integrated into CNC machines to optimize performance and anticipate maintenance needs.

15. How Can You Find the Right CNC Machining Service for Your Aluminum Parts?

Finding the right CNC machining service is crucial for ensuring high-quality parts. Look for a provider that specializes in aluminum machining, has the right equipment, and offers a track record of precision and reliability. When evaluating potential suppliers, be sure to ask about their experience, certifications, and quality control processes.

Conclusion

Aluminum CNC machining is a game-changer for businesses seeking precision, cost-efficiency, and quality in their manufacturing processes. By understanding the benefits, challenges, and best practices, you can make informed decisions about when and how to use aluminum for your parts. Whether you’re in aerospace, automotive, or electronics, CNC machining can help you achieve the results you need—on time, within budget, and with exceptional accuracy.

FAQ Section

Q1: What is aluminum CNC machining?

Aluminum CNC machining is the process of using computer-controlled machines to shape and cut aluminum into precise components.

Q2: How does CNC machining work with aluminum?

CNC machining works with aluminum by using cutting tools to remove material from a solid block, achieving precise shapes and dimensions.

Q3: What are the advantages of using aluminum in CNC machining?

Aluminum offers benefits such as lightweight properties, corrosion resistance, and ease of machining, making it ideal for various applications.

Q4: What are the challenges of aluminum CNC machining?

Challenges include tool wear, heat buildup, and achieving a smooth surface finish.

Q5: How can I find the right CNC machining service for my aluminum parts?

Look for a service provider with experience in aluminum machining, a strong track record, and the right equipment to meet your needs.